Moparts Tech Archive

Automatic Trans.

Solid Bands & Flex Bands

What are the pros and cons of a flex vs. solid front bandAuthor Topic: What are the pros and cons of a 727 flex vs. solid front band.

todd440

Moparts Member

Posts: 1268

From: lapeer,michigan

Registered: Jan 2001

posted 10-23-2002 07:11 PM

Enlighten us, please. Lots of choices when it comes to front bands.

========================================

69DartGT360

Moparts Member

Posts: 3013

From: State College PA.

Registered: Apr 2000

posted 10-23-2002 07:21 PM

Pros and cons? I hav'nt actually heard of anybody WANTING to use a flex band over a solid.... I think they're just considered weaker.... I've never had a problem with a solid red lined kickdown band yet..... Why fix something if it is'nt broke?

==========================================

John Kunkel

Moparts Member

Posts: 2606

From: Rio Linda, CA, USA

Registered: Nov 1999

posted 10-23-2002 07:35 PM

I prefer the flex band, it will distort when applied and grab the drum more evenly. The rigidity of the solid band allows it to apply more on one side than the other.

Most will disagree. Some claim that the anchor ends will bend under load, never seem it happen.

========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-23-2002 07:52 PM

I work in a transmission shop and agree with you Dart360GT. The solid band is better than the flex band. You very rarely see a solid band (low/reverse in a 727, reverse in a Ford AOD, ect.) wear out or break. I've seen countless flex bands burn up or break the anchors off of them. The builder and I were talking tonight about my 727 buildup and he suggested I run an intermediate (front band,2nd gear) solid band.

Rob

==========================================

Leigh

Moparts Member

Posts: 1989

From: Scratched Pan, MN

Registered: Mar 2000

posted 10-23-2002 08:21 PM

I consistantly get 500+ passes out of the iSonnex kevlar rigid band that Paul sells @ T/A. Of course, this is a race only deal. For a street car, I use flex bands all the way.

===========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

posted 10-27-2002 09:40 AM

I am interested in this topic.

I agree from a theoretical standpoint that the flex band should work better. As long as they are strong enough for the high apply pressures used in race transmissions. That trans shop experience with band failure is enlightening.

Being a newbie trans builder, I have only built the one in my Dart, but more are coming. The Dart has a solid red lined band and a Griner valve body at 180-190 psi. Maybe the next trans (roller effort) should use a flex...

==========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

I'm in the process of building my 727. I was even considering doing a write up or tech article for posting on here during the buildup. I'm not sure if its really needed or wanted though. My 727 is a 68-69 vintage that is getting several updates. It currently has the 4 clutch high and 4 clutch forward drums, but also has 3 pinion front and rear planets. After checking everything out and seeing how I would have to change alot to use the Hemi high drum, I've decided to stick to the drums I got. The planets are being changed to an aluminum 4 pinion rear planet and a 5 pinion steel front planet. In order to do this, you have to get a 76-up output shaft because the splines on the front planet carrier are different. The clutch packs are getting Raybestos blue clutches and Kolene steels, with the wavy high drum snap ring being replaced with straight one from a Turbo 400 for reducing some of the clearance. Since I'm using the normal type front drum, I've opted for a solid front band,a 5.0 ratio lever,and a reinforced band strut from A&A transmissions.The factory kickdown band strut has a bad habit of breaking. The low/reverse band is a solid kevlar lined band.For a valvebody, I've chosen one from A&A transmissions. Its a fully manual reverse pattern valvebody that applies the low/reverse band in 1st gear. This takes some of the pressure off of the sprag and will enhance street driving reliability. The sprag by the way is a bolt-in unit for added strength. This is basically everything, along with a deep pan and large transmission cooler w/ electric fans. A converter from PTC will round out the package.

Rob

==========================================

Leigh

Moparts Member

Posts: 1989

From: Scratched Pan, MN

Registered: Mar 2000

posted 10-27-2002 10:32 AM

Rob, that build will work great. It could be the basic build for 99% of the car's on this board.

==========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

I am running a 3.8 lever since Griner recommends that for my application with their high pressure valve body (race). I think a 4.2 with lower pressure (Turbo Action) or higher power (>650 hp) is common. The 5.0 lever is not bad, but it seems the big name trans guys don't like them for racing.

A&A sells a steel body, 5 pinion planetary for the front of a 727, $395 (ouch). The catalog says specify year, so they sell a pre-'76 version.

You can put 5 frictions in the 4 friction front drum. See my website for the machined pressure plate, Turbo Action sells it too.

727 Trans Mods

I would be interested in an article from you!

P.S. This is the heavy duty front band strut I make. Maybe I should make a rear one too? I figure it was so short it wasn't a problem...

===========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-27-2002 10:37 AM

I believe that the solid band is the ticket in a performance application. I'll check into the pressure plate and see what I come up with. To be honest, not really sure if its worth the added money since I'm using the Raybestos blues and Kolene steels. The frictions are pretty large in both the forward and high gear drums, allowing quite a bit of load carrying ability. Thanks for the info again.

BTW, very nice website Jim,lots of good info there!

Rob

===========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-27-2002 11:08 AM

jim , nice front strut , the ones i get are thicker in the middle and have more of a bevel on the ends to clear parts . i'll try and post up a pick i have a couple extra .

smokin , 5 clutches would be a good upgrade , i do it in my 47RE behind my diesel , the power i'm making makes short work of the 4 clutch pack even with increased pressure (85psi idle , 150 WOT ).

company i get my parts from makes a billet alum piston that is more uniform than the cast piece the factory uses and they machine down the pressure plate and use a combo of thick and thin frictions to get the desired clearance . also uses a raybestoes hi energy flex band for the front , but this is a street application so its probably the better way to go .

does 5 pinions add frictional drag inside the trans ? are the 5 pinion carriers the same as used in the later 618 trans ? i have one from a core i bought and if they are i know i can get them cheaper than $395 .

==========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-27-2002 11:12 AM

John, not sure about the frictional drag...it would have to be very minimum,if any. The 5 pinion planets I'm going to use are factory 618 units.

Rob

==========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-27-2002 11:14 AM

cool , smokin should be able to buy them from a place like transtar and possibly even mopar for alot less than A+A charges. i'll check tomorrow and post what i find .

==========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-27-2002 11:15 AM

I work in a transmission shop...it has its benefits . Just remember that if you want to use the 618 front planets that you have to get a 76-up output shaft since they changed the splines and spline angle on the planet carrier.My 68-69 output shaft wont work with the 618 front planets...already tried it,was a no fit situation.

Rob

===========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-27-2002 11:23 AM

thanks for that heads up , not a problem , i know a guy at a trans shop and he sells me used output shafts for 20 bucks . i'll get another this week .

==========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

posted 10-27-2002 11:31 AM

The trans I am going to rollerize is a '78 727 with the 37.5º spline shaft for the front planetary. A steel splined, 5 pinion, would be nice if the price is reasonable (not $395). According to my notes, the front planetary splines are:

'62 to '75: 45º

'76 to '93: 37.5º

'94 and later: 30º

JohnRR, what is the thickness of the band struts you use? I just picked a size. This thing is way beefier than the stock one, the pic doesn't do it justice. Superior also makes a heavy duty front band strut.

==========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-27-2002 11:55 AM

jim , i had the superior in it originally , my supplier changed to these he had made himself . i'll go grab one . it measures .246 .

good heads up on the spline counts jim , that means that the there isn't a way to use the later ones wit hthe 618 parts as mopar stopped making 727's by 94 i assume ??? if this is the case A+A is making their own or you are also getting an output shaft with the planet ???

==========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

posted 10-27-2002 12:04 PM

What years were the 618 (or any steel splined front planet) made from the factory?

My '78 came with a 4 pinion, aluminum splined planetary. In my '67 trans, I got a used 4 pinion, aluminum splined planetary for $40-$50.

========================================

MRMOPAR

Moparts Member

Posts: 1520

From: Tucson, AZ

Registered: Jan 2000

posted 10-27-2002 12:05 PM

I machined a pressure plate down to the dimensions shown on 451s page. Using that in a 3 clutch front drum with std thickness plates, we were unable to get 4 clutches into the drum and still set the clearances correctly even with the thinest snap ring. We then machined the pressure plate from the forward (rear) clutch drum down (removed some of the "ridge" that the bellvied spring operates against) and it worked no problem.

I have never had a problem setting the front drum clearances replacing the wavy retainer spring with one of the flat ones available from Mopar so am not sure why there was a comment about using one from a TH400.

I run the 3.8 lever with a Tranzact Brake and red solid band. The front drum has 5 clutches using a thinner set of frictions from Dave Smith at ProTrans.

I have seen some instances of the Kevlar band glazing over and slowing the car a bit. Some people seem to have better luck with them than others. I stayed with a known quantity.

===========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-27-2002 12:09 PM

My ATC catalog that we use to order parts at work lists 2 sets of 5 pinion front planets, one aluminum the other steel. Here is what the listing in the catalog says "Planet, A727/A518/A618 Front (5 gear)". It doesnt state a year or spline angle. Another listing for a 4 pinion front planet reads "Planet, A727/A518 Front (4 gear) 1976-up". There is also one that reads "Planet, A727 Front (4 gear) 1965-1975". So, from what I can gather, they changed the planet spline count and/or the spline angle in 1976.

The TH400 snap ring is thicker and stronger is the reason.Its not a necessity to use it, but I have one available and will be installing it to replace the wavy snap ring.

Rob

=========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

posted 10-27-2002 12:30 PM

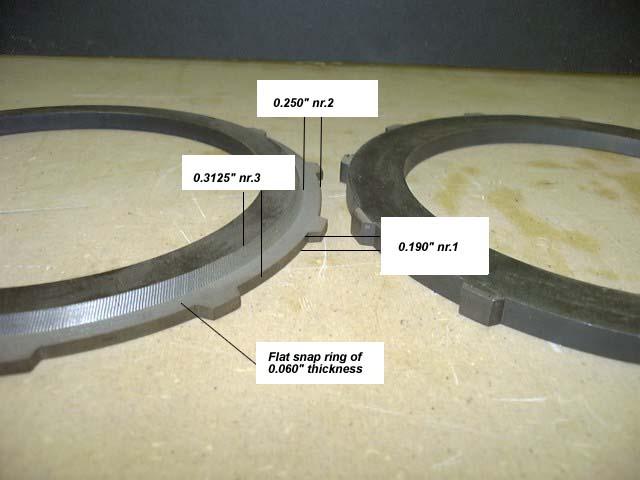

My notes show the Chrysler snap rings:

1942063: 0.060"

1942064: 0.074"

1942065: 0.088"

2466811: 0.106" I bought this one last year.

===========================================

MRMOPAR

Moparts Member

Posts: 1520

From: Tucson, AZ

Registered: Jan 2000

posted 10-27-2002 01:16 PM

I understand the 400 snap ring "may be" thicker and "may be" stronger, but you are still limited to how thick the snap ring can be based on getting correct clearance in the front drum. I have never set one up (many over the past 30 years) where one of the Mopar snap rings (PNs listed above) have not worked correctly.

=====================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-27-2002 01:20 PM

The 400 snap ring comes from the builder that I work with who has 20 years experience building all makes of transmissions,from bone stock to flat out race units. I take his word on using the 400 snap ring. I'm sure the Mopar units work just as well, but like I said earlier...we got a 400 ring there,so I plan to use it.Just my opinion on parts to use,thats all.

Rob

===========================================

Leigh

Moparts Member

Posts: 1989

From: Scratched Pan, MN

Registered: Mar 2000

posted 10-27-2002 02:29 PM

My experience is that I rarely can pin down the exact spec I need without useing some combination of +.015 steels and the various snap rings.

==========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-29-2002 07:45 PM

JohnRR, got a used '76-up 727 27" long output shaft and a brand new 5 pinion steel front planetary today. They match up fine,no problems at all. The planet was a firm fit on the output shaft,not loose or binding up. Just thought I'd pass it along to you.

Rob

=========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

i'll look in my transtar catolog , i bet the mopar and 400 snap rings are the same part number .

there is a front pump bushing for a 400 (350??) that fits in the 727 , is got a tad tighter OD , works well for convertors that have a slightly undersize pump snout .

heres the pics of my strut

and billet front piston

============================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

posted 10-30-2002 08:37 PM

Billet front piston, wow.

I thought my custom strut was heavy duty, Superman couldn't bend yours!

smokindatires, what is the year and application of that 5 pinion steel spline planetary? That would be a nice upgrade for the '78 trans I plan to rollerize. Cost?

===========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-30-2002 08:45 PM

Not sure of the year they went to the steel 5 pinion planets, but they came in A518/A618 transmissions. I want to say 94 but not am entirely sure.

Rob

===========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-31-2002 12:01 AM

thanks jim , those parts are going in the trans behind my cummins along with a billet input shaft , the factory pieces are known to break under the power of a BOMBed cummins . i do have an extra of each that was slated for the spare trans for my truck , they may end up in the dart though , the piston is machined about .060 thinner , this with the correct combo of steels ,frictions and snap ring gets almost any clearance i want .

smokin , i checked in my transtar cat , they have no listing for snap rings for turbo 400 only a snap ring kit for a turbo 350 ????

===========================================

smokindatires

Moparts Member

Posts: 658

From: Valdosta,Georgia

Registered: Jan 2002

posted 10-31-2002 06:23 AM

John,a turbo 400 ring is not a necessity, just something you can use if you have them. The snap rings from Mopar work just fine.I've since changed my mind and am going with a snap ring and pressure plate from Turbo Action. Their snap ring and pressure plate lets you put 5 clutches in a 4 clutch drum.

Rob

==========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-31-2002 07:10 PM

smokin , the piston i posted and the pressure plate that comes with it allow me to also do 5 in a 4 , and i can use any of the snap ring sizes to set clearance .

==========================================

todd440

Moparts Member

Posts: 1268

From: lapeer,michigan

Registered: Jan 2001

posted 10-31-2002 07:48 PM

John, who makes/sells that piston?

===========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 10-31-2002 07:53 PM

todd , i get it from a diesel trans shop in oh canada . i'm one of their test dummies ... same place i get that strut . if youn need a dodge or ford diesel trans upgrade this is the place to call .

diesel transmission technoligies , 866 504 4002 .

===========================================

don miller

New Member

Posts: 11

From: victoria bc canada

Registered: Sep 2001

posted 10-31-2002 08:31 PM

For any one that's interested in either the struts or the piston and drum, they are made by a company here in Langley, BC. Their web addy is www.tcsproducts.com or if ya want a phone number 1-800-960-1177 ya could ask for Bob Marshall (owner) or his son Rob tell em I sent ya.

==========================================

451 Jim

Moparts Member

Posts: 2448

From: Lexington Park Maryland

Registered: Dec 2000

I made my own "5 disc" pressure plate, copy of the Turbo Action (or TCI?) part. I just machined a stock one on the lathe. I like this!

Machined front pressure plate

440Jim's Mopar Web Site

===========================================

chilort

Moparts Member

Posts: 193

From: Arcadia, IN USA

Registered: Nov 2001

posted 10-31-2002 10:36 PM

Flex band, 700hp, no problems; two seasons in a row in two different cars.

Transtar, look there for good prices on parts!

===========================================

JohnRR

Moderator

Posts: 10082

From: Ma.

Registered: Nov 1999

posted 11-05-2002 11:14 PM

don , i've had a walk thru of tcs , very impressive operation ...

i think that the piston alone will work in the gas race application as you need tighter clearance than what i'm told to run my 47RE at ...

==========================================

Tech Index