Moparts Tech Archive

Big Block

Stage VI head questions

v8440New Member

Posts: 2

From: Montgomery, AL

Registered: Jun 2002

posted 06-30-2002 01:02 AM

Hi all,

I'm about to install a set of stage VI heads on a 440 for my '86 ramcharger. I've never worked with these before, so I have a few questions: 1. What sparkplugs do they use? 2. Do they use regular headbolts like stock iron heads? 3. What do I have to do to seal the valley and intake ports up with these heads on the RB block? If anyone can shed some light on this, I sure would appreciate it.

============================================

TA152H1

Moparts Member

Posts: 595

From: Maple Shade, NJ USA

Registered: Sep 2001

posted 06-30-2002 02:22 AM

I can help you with #3. Mopar makes a special valley tray for the Stage VI's. 4876847 for the B blocks

4876848 for the RB blocks.

You probably already know, but you'll need to use Stage VI 440 intake manifold spacers when using Stage VI heads with an RB manifold on an RB block.

Pete

===========================================

reddodgehemee

Moparts Member

Posts: 143

From: bristol,indiana usa

Registered: Mar 2002

posted 06-30-2002 02:30 AM

Also yopu use either a smallblock plug or hemi plug brand heat range personal choice the big block plugs do not have long enough reach

===========================================

thunderhead

Moparts Member

Posts: 1453

From: Tucson, AZ

Registered: Aug 2000

posted 06-30-2002 04:12 AM

v8440, did you have to do any "extra" work to get the heads ready to use? Just concerned about all the negative feedback on MP Stage VI heads thats been going around.

Thunderhead

===========================================

v8440

New Member

Posts: 2

From: Montgomery, AL

Registered: Jun 2002

posted 06-30-2002 09:54 AM

Thanks for the answers, I had to get the deck surface milled on my heads because I bought them used. I also had to get a number of other things done, all related to the fact that they were used. So, to answer your question, I really don't know what things might have to be done with a new set. What negative things have you been hearing about the heads?

===========================================

clutch

Moparts Member

Posts: 494

From: Spring Lake MI USA

Registered: Mar 2001

posted 06-30-2002 10:36 AM

I run a set of those on my stroker I usually run autolite 64 or 65's. I would run a head bolt with a washer like ARP's other than that they are stock length on the bolts.You can fabricate your own Valley tray theres not much to them. I made my own with some aluminum hold down bars for the ends.

============================================

Porting results w/ MP Stage VI templates

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-04-2002 02:33 AM

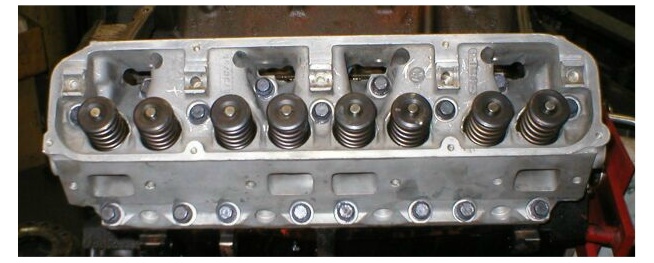

No doubt that the best "bang for the buck" standard-port big-block Mopar head right now is the Edelbrock. However, some of us went w/ MP Stage VIs before the E heads were ever released (or even conceived). I don't know how many people are sitting on Stage VIs, or can get a set cheap enough to be worthwhile (they'd have to be pretty cheap, IMO), or already have them in some mildly modified form. Regardless, this information may be helpful to those of us who _aren't_ using Edelbrocks.

My 452 RB has a set of MP Stage VI heads smoked over by Porter Racing Heads (aka "fast68plymouth" on Moparts). Since I try to be a "do it yourself" kind of person - at least on stuff I like - I plan to do the porting on a second set of Stage VIs I picked up as spares last year. Given this level of work is more extensive than porting I've done before, I also found an untouched early Stage VI casting (one of the original run from the foundry w/ the porosity problems) cheap enough to use as a guinea pig for porting. Out of the box, w/ the MP valve job, the "experimental" head wasn't very impressive:

lift-------in / ex

.100--66.5 / 52.7

.200-142.8 / 102.7

.300-201.9 / 123.8

.400-232.5 / 131.9

.500-246.8 / 135.6

.600-246.8 / 136.9

.700-251.6 / 138.3

This was actually the best of all four intake ports by almost 5 cfm. However, all the exhausts maxed out at 138-139 cfm (in other words, all were consistently bad!). Anyway, I got the bug up my butt to see how easy it was to get some reasonable #s out of one. I fiddled w/ one cylinder doing nothing but some bowl blending and minor profiling of the short-turns. There was w/ no work at all on those big-ass guide bosses:

lift-------in / ex

.100--66.1 / 56.9

.200-142.8 / 109.0

.300-207.5 / 151.8

.400-239.5 / 170.2

.500-257.0 / 183.4

.600-266.5 / 191.9

.700-268.1 / 194.3

Obviously, the exhaust picked up way more than the intakes for such a minimal amount of work.

Then, using a combination of what I'd seen with the PRH heads and the MP templates to fall back on, I went back into the intake port to reduce the guide size (what a freakin' pain!), more blending in the bowl, and some additional work on the short turn. No work past the bowl area at all, so the rest of the port was as cast. This was still just a cuttered finish except some minor polishing of the short turn - and ended up with the following results:

lift-----in

.100--68.5

.200-145.4

.300-213.2

.400-253.1

.500-274.0

.600-284.7

.700-290.0

I'm no pro porter, but I'm no hack either. IMO, this is close to what can be expected from somebody who does a careful job w/ the MP templates.

However, I compared the results to the PRH heads and noticed I wasn't seeing very big #s at .500-.600", although the .100-.400" #s were as good or better. This isn't necessarily a reflection of my porting, because the latest generation Stage VIs, of which my first set are, don't seem to have as good low-lift #s compared to the earlier castings.

With some minor additional profiling to the short turn, more trimming of the guide boss, smoothing the ridges & high spots left in the bowl from the previous work, hand-blending a steeper angle into the bowl from the 60-degree cut below the 45-degree valve seat, straightening out the cylinder-side wall where it merges into the bowl, and opening the pushrod pinch area to approx. 1.10+", I got another 5 cfm at .500"+, which wasn't much for the time I spent doing the work noted. I started experiencing the law of diminishing returns rather quickly.

lift-----in

.100--69.0

.200-146.3

.300-214.4

.400-254.7

.500-279.4

.600-290.1

.700-295.4

At this point I was swapping e-mail w/ Dwayne Porter because, to be blunt, I thought I'd done a fairly decent job of copying much of what he'd done w/ my other heads and wasn't seeing as good results. For comparison, here is the average of all eight intakes for the PRH heads:

lift-----in

.100--67.5

.200-141.7

.300-204.3

.400-252.5

.500-287.5

.600-306.7

.700-309.9

One of the key areas we discussed was the short turn. Me being me (i.e., always thinking of trying something different), I didn't copy Dwayne's short-turn profile. Instead, based on some stuff that Steve Dulcich had written and other heads I'd seen or read about, I put a more convex shape to the short turn, thinking this would help the flow at higher lifts w/ less turbulence I'd seen w/ my first heads. Well, maybe that wasn't the right thing to do w/ the Stage VI after all... I tried "fixing" the short turn based on what Dwayne told me worked well for him, opened up the width of the port at the short turn, plus increased the bowl area slightly on the long-turn side, all in my attempt to reduce the velocity into the bowl and help the air turn.

lift-----in

.100--68.5

.200-147.3

.300-214.4

.400-251.5

.500-277.6

.600-288.3

.700-297.2

OK, obviously that was a waste... and the loss of 2-3 cfm between .400-.600" didn't exactly bring a smile to my face. Anyway, I'm probably done messing w/ this port and will try something different on the short turn w/ the next one.

Now, to be realistic, this isn't horrible for an under-210 cc port (forget what MP claims, these measured 193 cc w/o any porting, IIRC) and compares reasonably well to some other small-port heads. A "good" uported cylinder from 440/451 Jim's Edelbrocks (they seem to have "good" and "not as good" intake ports, from what I've heard) showed this on my flow bench:

lift-----in

.100--71.7

.200-143.9

.300-212.3

.400-253.0

.500-276.9

.600-287.0

.700-290.4

An out-of-the-box (does anybody actually run one "out of the box"?) Indy SR w/ a 260+ cc port volume generated these results:

lift-----in

.100--64.5

.200-136.5

.300-201.3

.400-246.9

.500-278.7

.600-295.5

.700-295.6

Also, we tested two Edelbrock ports Jim modified somewhat (no huge changes) and came up w/ these results. Since he did comparable mods to both, I think what you've got here is an example of those "good" and "not as good" ports I mentioned above...

lift----- #3 / #1

.100--69.6 / 68.1

.200-142.8 / 141.0

.300-209.7 / 210.9

.400-256.4 / 256.4

.500-283.5 / 275.5

.600-295.5 / 288.8

.700-299.2 / 293.8

Oh, so what happened to the Stage VI exhaust port, you ask? Well, that port got treated to the MP template job, too, along w/ _minor_ additional work I did "just because". I didn't open the port size any, nor did I mess w/ the cast-in bias to the outside wall. Once again, this is probably typical of what Joe Average could do w/ the MP templates. I've listed results both with and w/o a 2" "flow tube" that Jim Hanrahan made me.

lift--- w/o / with

.100--55.8 / 56.8

.200-108.4 / 113.2

.300-153.6 / 156.4

.400-179.0 / 191.0

.500-198.3 / 215.1

.600-209.1 / 230.8

.700-215.3 / 241.9

Once again, I've got out-of-the-box Edelbrock exhaust port results courtesy of Jim Hanrahan's heads:

lift--- w/o / with

.100--53.7 / 56.2

.200-103.6 / 115.0

.300-145.5 / 155.5

.400-178.4 / 196.5

.500-194.1 / 218.2

.600-202.3 / 230.9

.700-207.1 / 238.9

However, compared to the PRH-ported exhaust ports, my MP-template job is pretty weak at high lifts. Here are w/ and w/o flow tube results:

lift--- w/o / with

.100--52.7 / 53.1

.200-102.7 / 106.9

.300-144.6 / 152.5

.400-183.2 / 192.8

.500-214.5 / 232.5

.600-237.3 / 259.6

.700-250.0 / 275.5

Jim also came up w/ some really respectable exhaust port #s from his Edelbrocks based on porting guidelines Dwayne provided. Once again, these are w/ and w/o flow tube:

lift--- w/o / with

.100--53.9 / 56.0

.200-114.3 / 118.9

.300-155.6 / 165.6

.400-191.5 / 207.1

.500-215.6 / 228.3

.600-228.4 / 252.3

.700-234.7 / 263.4

So, what was the point of all this? Crap, I figured somebody would ask...

First, I've learned that getting _big_ #s from these heads isn't as simple as DIY porting using the MP templates. However, the results from that level of work are still an improvement over the ported OEM '452' heads that put my junk into the 10s on pump gas. Here are flow #s from my old my old ‘452’ heads (average for two cylinders tested). Although not taken from the same bench as other flow #s shown here, I believe they're close enough for comparison:

lift-------in / ex

.100--70.6 / 58.1

.200-146.2 / 106.9

.300-201.7 / 148.8

.400-241.5 / 177.5

.500-265.8 / 197.1

.600-278.3 / 205.0

.700-284.2 / 209.6

Here I've consolidated the results for the work I did while, basically, following the MP templates:

lift-------in / ex

.100--68.5 / 55.8

.200-145.4 / 108.4

.300-213.2 / 153.6

.400-253.1 / 179.0

.500-274.0 / 198.3

.600-284.7 / 209.1

.700-290.0 / 215.3

Second, I'm not sure who I want to bitch-slap more... Edelbrock for not having released their big-block Mopar head six months earlier so I could have bought those instead of my Stage VIs, or MP for selling the Stage VI head in such rough form (and w/ a variety of quality control issues) that it takes significant extra work (and $) simply to equal the Edelbrock out of the box.

Third, may I suggest that any back-yard porter contemplating doing anything more than a basic bowl blend and gasket match to their heads think twice. Hell, I've got a flow bench of my own to test my work and still spent more time than I want to admit grinding on my heads for little or no results. If you don't have some pretty good directions to follow (like the articles Steve Dulcich wrote on porting MP Stage V and W-2 heads), you're just as likely to be making things worse as better.

=========================================

dulcich

Moparts Member

Posts: 478

From:

Registered: Jul 2001

posted 08-04-2002 03:03 AM

Brad,

You seem to be really down on the stage 6, but it looks to mee like they work really well with just some minor bowl and SS clean-up. If they were finished to that level fom MP, everyone would think they're great. The E-head, on the other hand, already come finished very nicely at the bowl and SS, hand blended, and with the valve job all the way out to the major valve diameter. Measure the seats on the MP head, any you may find they are only about 2.10"

Do you have a pic of the SS mods? Like to see what you had done. I recently did a set of MP BB Alum heads (these are the standard port location heads based on the 6) and found a big run up in the floor (sky-jump). Did massive SS work including drastically reducing the sky jump, and they last tested at 310, about the same across the curve as a fully ported Edelbrocks I had done(which are cast flat in the floor, without the skijump). Played with the MP's some more, but haven't re-tested. Maybe you didn't go far enough, or left a ridge where the work from the bowl side meets the work from the runner side. Run your finger along the short turn, and it should drop away to meet the floor in a smooth continuous radius. Thanks for sharing the info.

-dulcich

dulcich

Moparts Member

Posts: 478

From:

Registered: Jul 2001

posted 08-04-2002 03:11 AM

BTW-

have you taken cross sectional area measurements? Measure at the pinch and over the short turn. If untouched you may only have just over 2" over the SS. This area is kinda tight, with a tall STG-6 floor, the spring recess limiting the height of the roof, and the boltbulge on the OS wall. If it measures as small as I think it will (I've never worked on the 6) 290's will be an amazing amount of air through that little hole.

==========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-04-2002 10:31 AM

Steve D. - I'm only down on the Stage VIs because they're way overpriced compared to the Edelbrocks, and they've had (especially the latest ones) some real quality control problems. The set PRH did for me needed new guides right out of the box, the valve heights were all over the place, the chamber volumes between the pair of heads (even after equalizing the valve heights) weren't even close, and the exhaust ports have a lot of core shift which results in "good" and "bad" ports. Also, even though MP talks up their "out of the box" valve job, the latest heads like those looked like the seat cutters were way past needing replacement. It cost almost as much to straighten out the MP QC issues as the porting did. My second set, which are a previous generation that still have the hughe valve guide bosses and were CNC-machined in the chambers, aren't nearly as bad as far as seat height variation or core shift. However, the chambers are so wide that they'll need to be milled about .100" simply to make them fit w/in the fire ring of a head gasket, I suspect the guides are (yet again) too loose, and one of the alignment dowel holes on each head isn't even drilled in the right location. If they sold 'em for $349 each bare, some of this would be easier to rationalize. But at $700+ each bare, it's tough to justify.

Other than the price and QC issues, I happen to think they've got a lot of potential. The chamber design is much better than the Edelbrock's and the raised intake port should be able to translate into a flow advantage. No doubt they can be effective parts, but they're certainly not _cost_ effective. Also, if I was only running a .500" cam, instead of .600+", the intake #s I've achieved already would look pretty decent. However, w/o being much larger in any particular dimension (and smaller in some), my first set of heads pulled much harder @ .500+", and the best of those ports were over 310 cfm @ .700".

As far as port measurements, the way I did it was to start at the port entry and go in approx. 1" w/ each increment. The closest thing to a short-turn measurement was the height taken 3" in from the entry, and the width taken approx. 1.5" back from the centerline of the guide into the throat.

Entry - 2.16 H x 1.15 W = 2.48 sq in

+ 1" -- 1.95 H x 1.13 W = 2.20

+ 2" -- 1.76 H x 1.28 W = 2.25

+ 3" -- 1.69 H x 1.61 W = 2.72 (width measured approx. 1.5" back from the centerline of the guide)

I wish I had a digital camera to take pics of my work, because I figured you'd be interested in seeing how I did the short turn. The transition from the runner floor to the drop into the bowl seems pretty smooth to me. If anything, I may have carved away too much of the short side attempting the convex form (it's pretty freakin' laid back). The floor is lowered slightly starting just past the pinch point (as suggested by Dwayne), but I didn't take a huge amount out here. Previous velocity probing I did on the PRH heads surprised me because the floor, especially approaching the SS turn, was much more active than I'd expected. This made me wonder if, contrary to most people saying not to lower the floor and concentrate on the roof, these heads might respond to additional work there.

You're correct in that the MP valve job short-changes the benefit the large(r) valve because the seats aren't placed far enough out on the valve to take advantage of the valve's full potential. However, I'm working w/ the out-of-the-box valve job at this point.

=========================================

dulcich

Moparts Member

Posts: 478

From:

Registered: Jul 2001

posted 08-04-2002 11:23 AM

Brad,

Thanks for the reply. The point I was trying to make is that the 6 isn't a bad head inherently by design, just the details and QC let them down. IMO, you should go in and cut more in the runner. At on a little over 2sq", the heads are very small for a race BB. On my SB E-heads I have no less than 2.34sq" at the smallest point, and my MP heads are about 3sq". Flow potential is aboout 145CFM per 1sq", so geting more isn't so much a matter of form as size. Rather than take measurements at equal increments, measure where the contraints to size are. Take a marker and draw a ring inside the port, so that a measurement can be taken with a fair degree of accuracy. Remember too that the port enterance is at an angle, so the apparent enterance size is larger than it really is.

==========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-04-2002 11:30 AM

Steve - If you've got any images of what you did to the MP head that you can e-mail me, please do. I'm interested in seeing the extent of the work. Also, I'd have contacted you directly about questions re: the convex short-turn form, but I suspect you guard your e-mail address like Fort Knox! LOL

Jim - IIRC, we didn't do a "before" test of your modified #1 port, only the #3. We don't really know how much #1 improved w/ the riblets, only that it wasn't as good as the other port. The dyno session will most likely be at C&C Performance in Manassas, VA. I'd rather to go back up to Dwayne's, but it's too freakin' far to go... I'll let you know more when I've actually made the arrangements.

=======================================

Unlawfl

Moparts

Posts: 6120

From: bloomfield hills, mi, usa

Registered: Jan 2000

posted 08-04-2002 11:38 AM

Brad, excellent, excellent info. here. I think you're making a real valid point about the VI heads. They CAN work, but at this point unless you get them real cheap, or have them already, why??

Will everyone that has purchased a set of brand new Stage VI heads from MP over the past 6 months please chime in here... (crickets chirping in background) If MP does not address the QC issues and price these things competitvely and in ready to run form, theyre going to go away real quick..

Thanks for the info. Brad. The day will come when its all back together and the work you are doing now will pay off. Watch and see.

==========================================

451 Jim

Moparts Member

Posts: 2568

From: Lexington Park Maryland

Registered: Dec 2000

posted 08-04-2002 12:00 PM

Your right, we didn't do before and after on #1. I did feel around more in all the runners to try and duplicate the small changes in #3. A pro would know how to get these over 300 cfm, but not me!

===========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-05-2002 08:48 AM

Bad Hemi - I don't have part #s in front of me, but can probably dig some of them up later. IIRC, there has been one part # for the "standard" Stage VI head since they were introduced, but that head has gone through a couple of changes in the last 10 years (first a foundry change the, later, changes to the guide bosses primarily). I have also seen part #s for unported assemblies, ported assemblies w/ 2.14" & 2.18" valves, CNC-ported assemblies, and bare heads w/ CNC-machined chambers, not to mention a couple variations on the Max Wedge version. I doubt I could find them all, between discontinued and/or superceded stuff.

My test head is an early original from the no-longer-used foundry (recognizable by a different foundry symbol). My first set are the latest generation w/ the smaller guide bosses (and, apparently, even more quality control problems than the previous ones). My second set has CNC-machined chambers, which I've seen as a separate part #, but came in boxes labeled w/ the standard part #. Go figure...

==========================================

jyrki

Moparts Member

Posts: 1717

From: Vantaa, Finland

Registered: Nov 1999

posted 08-05-2002 09:08 AM

I have a set that was made in '91. I bought them for a decent price in '92 (~1000$ complete) and portedthem. Don't have a flow bench, but our pump gas '451' made 649 hp in the dyno on pump gas with them. Last winter I wanted to add the port displacement and did that too. I raised the mouth of the port cosiderably, then going towards the valve I widened and slightly angled the floor ending up with 220cc ports. No flow bench results, but so far in the initial testing it seems that we have more power than previously. In the winter we should take the engine to dyno and see how it compares with the previous results.

==========================================

fast68plymouth

Moparts Member

Posts: 3354

From: so burlington,vt usa

Registered: Aug 2000

i recently freshened up a set of stage VI's for a customer who originaly got them from MM.

they had the std "stage II" porting.

its an older set of heads, but not the first generation.

they did have the huge guide bosses, and even after the MM prep still had the valve depths varying .050+.

they had a couple of seasons or so on them, and it was time for a freshening.

the customer asked me to flow test one, to see where they were flow wise, and then was going to make a decision as to whether or not more porting would be done based on the flow numbers.

i only tested one cylinder, as the work looked reasonably consistent from port to port, and i didnt feel any of the ports would have a huge difference in flow from another.

this is what i got as the heads came to me:

lift-----in/ex

.100---67.3/55.1

.200--143.5/107.5

.300--213.2/146.2

.400--260.9/159.9

.500--287.0/172.0

.550--287.0/178.0

.600--288.7/181.7

.650--290.5/185.3

.700--293.7/187.7

the intake flow was pretty much what i expected, but the exhaust flow was pretty weak.

the bowl was just too small, and they had left basically all the bias in the port...and didnt remove much of the guide boss at all.

the decision was made to go for some more flow, so i took that same cylinder and did the same basic work i did to Brads heads, however this is without putting the head on the guide and seat machine, and cutting the seats/bowls.

this was more of a test to see how much money it was going to cost to make a worthwhile gain in flow.

this is opening up the bowls free hand a bit, and back cutting the valves.

however, the majority of the time was spent narrowing the guides, and widening the short turn on the intake, and eliminating some of the port bias on the exhaust.

that work netted these results...same port as before.

lift-----in/ex

.100---67.3/53.1

.200--145.3/110.4

.300--214.4/157.1

.400--267.3/189.0

.500--301.1/207.1

.550--302.9/213.2

.600--306.5/219.2

.650--308.3/226.5

.700--311.9/231.4

i was very happy with the intake results, but i knew the exhaust numbers should be better still.

at this point i remachined the valve job, and slightly opened the intake bowl, and opened the exhaust bowl up a fair amount with a 75deg cutter.

then went back and took a bit more out of the exhaust guide, and removed even more bias.

on the intake, the 75deg cut was blended into the bowl and bottom cut of the valve job(60deg).

i also removed a bit more material from between the guide boss and the outside wall.

then before flow testing i touched up the seats, so this would be a test like the heads were ready to run.

this is how it ended up:

lift-----in/ex----ex w-tube

.100---69.4/58.2----59.7

.200--145.3/110.4--114.8

.300--213.2/156.2--165.3

.400--264.1/201.1--215.5

.500--299.4/220.5--244.9

.550--302.9/226.5--254.5

.600--310.1/233.8--262.5

.650--317.3/238.6--267.3

.700--320.9/244.9--273.7

the intake port openings were left the same size as the way i got them, in fact all the porting i did to the intake side was done from the pushrod pinch area inward.

the pushrod pinch width was 1.100...the same as the set i did for Brad.

this particular port seemed extremely stable to .700, so i figured id see how much the valve was actually holding back the flow.

here are the intake numbers for the really high lifts:

lift---flow

.750--322.7

.800--322.7

.850--326.2

1.00--335.2

and with the valve removed from the port completely, and just a stem in the guide to plug the leak the flow was 342.3.

it just so happens that while Brad was wrestling with his new stage VI test head, i was doing this set of heads. when his convex shape didnt appear to be working for him, i sent him these pics of what worked for me on the short turns of those heads.

looks like if MP had their act together, and had installed seat inserts large enough to accomodate a 2.20-2.25 valve...you'd be able to get closer to that 342cfm at a more usable lift.

in any case....im very anxious to hear how the car now runs with the extra flow.

===========================================

ZIPPY

Moparts Member

Posts: 5689

From: Detroit suburbs MI USA

Registered: Jan 2000

posted 08-05-2002 09:47 PM

Great info fellas, Brad/Dwayne, even though I am going to use the E heads it's still good to know you can do the same (if not better) with the 6's.

Not to hijack the thread, but since this was brought up earlier I have a Question:

What are your guys' thoughts on the

straight vs angle plug, and heart shaped vs max wedge shaped chambers?

I might imagine that the angle plug/heart shaped chamber would be the ultimate, but with these heads you can't have both at the same time!

Do the features cancel each other out to some extent?

===========================================

451 Jim

Moparts Member

Posts: 2568

From: Lexington Park Maryland

Registered: Dec 2000

posted 08-06-2002 11:38 AM

Great topic.

I was considering these heads during my early planning stages. They are a natural for the low deck (B) engine.

MM std "stage II" porting: .600--288.7/181.7

This supports my lack of confidence in their porting. I would have expected stage II to profile the guides better, open the bowl more etc. Maybe I expect too much...

PRH results: .600--310.1/233.8

Now that head should work well! Good job Dwayne.

That intake runner flows really nice now, the valve is the limitation.

========================================

J BODY

Moparts Member

Posts: 1038

From: Ft. Mohave, Arizona

Registered: May 2001

posted 08-06-2002 11:52 AM

Let's see, recent customer, MM stage 2 porting, I wonder whose heads those are? I've been happy with my stage VI's, although as Brad H said, with the choices out there today they would be pretty far down the list. I think when I bought mine your choices were Indy 440-1's, B1's, and the b1-bs had been released but I had little info on them so I passed (I still haven't actually seen anyone run those heads to this day). I saw a local racer running Stage VI's in a Dart that was running high nines on a fairly mild combo so I figured the potential was there for anything I wanted to do. It will be interesting to see what the car et/mph's at next time out.

=========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-06-2002 03:40 PM

"What are your guys' thoughts on the straight vs angle plug, and heart shaped vs max wedge shaped chambers?"

I'm going to shoot from the hip here and say that I'm not sure how much of an advantage of an angled plug really is. Is there supposed to be a combustion efficiency advantage, or is this one of those "Maybe it helps, maybe it doesn't." things? How much of the reason for them w/ small-block Chevies was to provide more clearance between the plug and the traditional domed pistons used to get high compression?

Re: chamber design, I think that's a little clearer. The old Max Wedge-type chamber doesn't appear to offer any significant improvement over stock in terms of swirl potential, vs. the modern heart-shaped chamber. The MW-type chamber also doesn't offer nearly the quench area that the old 915 iron head did. The chamber design was one of the few things about the Edelbrock heads that I was disappointed in, especially because their small-block Mopar heads use a modern chamber design.

==========================================

Benforsp

Moparts Member

Posts: 595

From: Ellenton, FL

Registered: Dec 1999

posted 08-06-2002 03:49 PM

451 Jim,

I have the MM VI's with Stage III port and surprisingly enough they flow 318-319 @.700. I don't have the hole sheet to post all of the numbers here, but if anyone is interested let me know and I can post them. It is good to see that Fast had numbers that would be consistent with the stage II vs my stage III porting. I was worried that MM may have a "Generous" flow bench.

Simon

==========================================

Prochargedmopar

Moparts Member

Posts: 1477

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 08-06-2002 04:10 PM

This does even more justice for Fast's port work that 451's listing at .600

MM "stage 11" @.700-293.7/187.7

PRH's "Stage ?" @.700 320.9/244.9

Fast68plymouth,

Could you post a couple pics of the exhaust work? Could you also describe a little more detail about the exhaust work? What's with the Exhaust "bias" you are refering too?

==========================================

ZIPPY

Moparts Member

Posts: 5689

From: Detroit suburbs MI USA

Registered: Jan 2000

posted 08-06-2002 04:15 PM

Thanks Brad.

I thought I remembered reading something like "the angled plug takes the plug tip out of the intake wash" but gotta admit I don't know what that means. The gas washes the plugs?

I guess if there was soap in the gas tank, then it would make more sense

The E heads do have an antiquated looking chamber, no doubt.

==========================================

Michael Doty

Moparts Member

Posts: 2177

From: T F, MT USA

Registered: Nov 1999

posted 08-06-2002 05:30 PM

One thing that some of the small heart shaped chambers do better,IMO, is help steamline and direct the flow on the chamber side.

==========================================

J BODY

Moparts Member

Posts: 1038

From: Ft. Mohave, Arizona

Registered: May 2001

posted 08-06-2002 05:32 PM

My biggest question on the MM porting was that when I purchased the heads and ordered the "stage II" porting I "assumed" that some kind of data sheet would be included. To my dismay there was nothing. I called MM and they pretty much beat around the bush, but I pretty much got the idea that I payed for an "eye ball" port job and from the exhaust numbers I must have only paid for porting on the intake side. Not much I could do from there. Thats why I was curious what the "as is" numbers were on my heads before I had Dwayne work them over for me. You'll have to look at it from the stand point of that this was also my first big block that a friend and I had ever put together, hell we didn't even know you had to notch the block to make the rods fit! (4.15 stroke) All in all I'd say we were lucky that the engine ran as long and as hard as it did. Best to date is a 10.70 @ 123. Next year? we'll see

==========================================

fast68plymouth

Moparts Member

Posts: 3354

From: so burlington,vt usa

Registered: Aug 2000

posted 08-06-2002 08:16 PM

Procharged...sorry...no pics of the exhaust.

i wouldnt even have the intake pics except Brad was looking for a "guide" for messing with his test head...and the two "test models" i had sent him are already bolted to his motor

as for the port bias, in simple terms, the inside wall and roof of the exhaust port are filled in a fair amount on the early stage VI heads, forcing much of the exiting air to the outside wall and that side of the roof.

on some ports having this bias helps the flow.

my experience with BB Mopar heads is that it basically just kills off flow.

on any type of BB Mopar head ive played with, removing the bias results in better high lift flow.

the reason Brads high lift flow numbers were better on the set i ported for him than this set was because the newer casting has most of the bias(and guide boss) removed already.

these ports could flow just as much as his did if i would have spent more time grinding metal away(that didnt need to be there in the first place), but since time is money...and i was at a point where the flow was considerably better than where i had started, i didnt feel i needed to spend any more of JBODY's money on exhaust work.

just look at a stock BB head exhaust port from the header mounting surface inward(they also have a very biased exhaust port) to get an idea of what i mean.

==========================================

Prochargedmopar

Moparts Member

Posts: 1477

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 08-06-2002 08:56 PM

Thanks Fast68plymouth,

Going outside to my workshop and take a look at one now.

Oh, and btw, What type of cc's did you end up with in/ex. Wondering how these heads stack up for heavy Street/strip applications compared to some B1's, Indy's or non mope competition heads.

Ok, After doing a little diggin, move parts washer, 2.2L crank, and toss the 10/10 440 crank outa the way, Presto! A BB head. Your right. Almost no gap what so ever between the valve guide boss and the inside wall. Basically none. Almost seems to be blocking that side of the valve totally from sight. Wonder how much meat is there? Thanks for the tip.

===========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

posted 08-06-2002 09:41 PM

Just wondering what the velocity is like in them heads, port design & contour have an effect on what maximum velocity the air can go & still follow the contour.

If the air is moving too fast along the floor around the short-turn radius it will choke off the flow & reduce the valve area.

It was a lot of reading but had that in mind when Brad mentioned something he did.

On the topic of angled plugs this is how I understand it, it moves the plug closer to the charge area & also the squish area, maximum turbulence is steered toward the plug to help combustion & pressure rise, good for using higher compression.

===========================================

rrsbdh

Moparts Member

Posts: 2144

From: Decatur Alabama

Registered: Oct 2001

posted 08-07-2002 08:12 AM

It is an interesting topic. Like maybe Edelbrock should try an buy Mp out of the heads and making them into a Victor. Seems they overpriced and under quality and that Edelbrock could make them the next move up if we could get those numbers out of the box and mp already has some for bigger valves too. Can you say gone in nine seconds. The 440-1 might have to sweat it if a set of them were in the next lane. I like the Mp head trick of using 440 intakes on b blocks and the Spacers for the big block. It would give the 440 manifold's a longer shot and we could run any manifold we wanted on em.

==========================================

J BODY

Moparts Member

Posts: 1038

From: Ft. Mohave, Arizona

Registered: May 2001

posted 08-07-2002 09:12 AM

That brings up another detail I was always curious about. How does that adapter affect head flow? I used to run the adapters with my M1 open plenum 4150 carb set up. I switched to the newer "stage vi" intake for a 4500 series carb. By the way swapping the 850 and intake/spacer combo, to the 1050 carb and intake dropped my et nearly four tenths and picked up four mph. It was after this little experiment that I really wondered if my heads could use more flow. My engine obviously reacted well to the increased air flow.

===========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-07-2002 09:23 AM

Fast One - I did some velocity tests w/ the heads that PRH did for me. If I can dig up the results, I'll see if they make any sense to post. BTW, I didn't do any air speed calc's, just mapping of manometer readings at different locations in one intake port.

JBODY - When Dwayne did my heads w/ the adapters, he straightened out the roof so as to eliminate the dip (although the drop in the floor at the junction is still there). My testing both with and without the spacers in place w/ this work done showed them to have a negligible effect on flow.

=========================================

fast68plymouth

Moparts Member

Posts: 3354

From: so burlington,vt usa

Registered: Aug 2000

posted 08-07-2002 01:38 PM

"JBODY - When Dwayne did my heads w/ the adapters, he straightened out the roof so as to eliminate the dip (although the drop in the floor at the junction is still there)."

what i did on that set of heads for Brad was to actually mount the adapters to the heads

with some countersunk screws.

then i ported the heads with the adapters in place, and all the flow tests were performed with the adapters.

========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

posted 08-07-2002 06:51 PM

I did wonder about the velocity because some port designs tend not to follow the contour if air speed gets over 350 feet/second, mapping the port flow velocity & graphing it's performance in the valve area would be quite interesting but also very time consuming, flow bench research can be quite addictive & I'm not surprised your car isn't finished yet ( ha, ha )

I feel that your disappointment in part of your test can be improved on without epoxy modification, even though I've only played with small block heads primarily the principles are basically the same, I'll have to read the post again.

===========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-08-2002 09:22 AM

Here's the port mapping exercise that I did on one of the PRH-modified heads. First, I mapped the intake port as six sections:

A - B (top left/right)

C - D (middle left/right)

E - F (bottom left/right)

Then, I measured the velocity w/in the port flowed .500" @ 10" (I've gotta SF-110, not a 600) starting at the runner entrance and at 1" increments into the port. The flow bench manometer reading did fluctuate some w/ the J-probe in the port, but was pretty much still @ 10" +/-. All the velocity readings are off the dedicated manometer hooked to the probe. The port measured was #3, so the cylinder-bore side is on the left and the divider-side wall is on the right.

At port entry:

A - 4.4 B - 4.0

C - 4.5 D - 3.8

E - 3.9 F - 4.0

1" into port entry:

A - 4.8 B - 4.0

C - 4.8 D - 4.2

E - 5.4 F - 5.2

2" into port entry:

A - 4.2 B - 3.4

C - 4.4 D - 4.0

E - 6.0 F - 5.2

3" into port entry (essentially right above short turn):

A - N/A B - N/A

C - N/A D - N/A

E - 4.4 F - 3.6

===========================================

fast68plymouth

Moparts Member

Posts: 3354

From: so burlington,vt usa

Registered: Aug 2000

posted 08-08-2002 09:35 AM

very interesting....im actually suprised the pushrod side of the port is the "busy" side for most of the way through the runner.

looks like my theory for opening up the roof between the guide boss and the divider wall was incorrect...although it may have worked for a different reason than why i did it.

what is most likely happening is that by opening up that area, more of the air column can occupy that space, which might help to slow the air on the pushrod side down a little as its going over the short turn.

your mapping does show how the air is sliding towards the bore center, which is what i thought was happening, i just didnt think that side was busier than the other side of the port at the short turn.

==========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-08-2002 10:05 AM

I looked at those results and had to double-check that they were for #3 and not #1. I'd also done some tests w/ a couple of intakes attached using manifold runners #3 or #6, so it was definitely #3 tested. "Truth is stranger than fiction..."

===========================================

TJ

Moparts Member

Posts: 277

From: Moberly, MO

Registered: Nov 1999

posted 08-08-2002 10:10 AM

fast68,

You mentioned you were surprised the pushrod side of the port is the "busy" side...

Is that an example of the "venturi effect" in action ? Where the port narrows for the pushrod, the air is picking up velocity as it travels over/around this, right ?

============================================

Prochargedmopar

Moparts Member

Posts: 1477

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 08-08-2002 01:20 PM

Normally one would think that the air column would be getting squeezed to the outside wall and then possibly crossover at the short turn crossing the back of the valve.

Maybe at a higher test pressure the velocity would pick up and start cramming it where it should be?????

==========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

posted 08-08-2002 07:22 PM

Well that is certainly interesting, especially 2 inches into the port & the lower left if I read that correctly.

The 915J head I did was opened up to 192 cc & flowed 283 cfm @ .600, at first I was doing great in the mid range but the higher lifts just wasn't responding & you could hear it on the flow bench, the air volume for the good numbers up higher was there but couldn't get through, too busy in the short turn area, in my frustration I opened the roof height 0.020 all the way from the entrance to the guide, YEEHAA !, pay dirt, instant success, in the end I think I opened it out to 0.060 more in the roof with improvements all the time in upper cfm.

Taking the extra out of the roof seemed to ease off the traffic jam of air around the short turn showing more valve for the air.

I've found that my best improvements for mid range cfm is in the pushrod side of the runner wall & upper cfm the roof.

The opposite side of the runner I do some work there but not too much.

I always give the guide area a good workout.

I'm very careful with the short turn, a little bit of work then onto the flow bench, a little bit of work then onto the flow bench again & so forth...

==========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-08-2002 09:14 PM

Bad Hemi asked about part #s for Stage VIs. I found '96, '99 and '02 MP catalogs and

have listed what they offered each of those years. You'll notice they've changed the

offerings a bit and there are numerous part number revisions.

1996

Standard, bare-------------------------------4529335

Standard, unmachined guides and seats--------5249051

Ported, assembled, 2.14"---------------------5249113

Ported, assembled, 2.18"---------------------5249523

1999

Standard, bare-------------------------------4529335

Max Wedge port, small chamber, bare----------5249579

"Street" Stage VI, non-raised intake port, bare------4876311

Standard, assembled (500/545 crate engine head)-----4876991

Ported, assembled, 2.14"---------------------4876186

Ported, assembled, 2.18"---------------------5249523

CNC-ported, assembled, 2.18", flat-tappet springs----4876382

CNC-ported, assembled, 2.18", roller cam springs-----4876383

2002

Standard, bare-------------------------------4529335

Standard w/ CNC-machined chamber, unported, bare----4876819

Max Wedge port, small chamber, bare----------5249579

Max Wedge port, standard chamber, bare-------4876818

"Aluminum 383/440" head, non-raised intake port, bare--4876311

Standard, assembled (500/575 crate engine head)----4876991

Ported, assembled, 2.14"---------------------4876186

Ported, assembled, 2.18"---------------------4876187

CNC-ported, assembled, 2.18", flat-tappet springs------4876382

CNC-ported, assembled, 2.18", roller cam springs-------4876383

===========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-08-2002 09:33 PM

Fast One - I agree raising the roof would help for the same reasons you mentioned. However, if you're not familiar w/ the Stage VI, one of the limitations is how high you can raise the roof because the raised port itself runs right under the spring seat near the base of the guide. Unfortunately, there's not much meat to carve on before seeing daylight from what I can tell. If the roof's height-limited and the floor's "busy", looks like lowering the floor may be one of the few ways to add much volume to reduce the velocity there. That's something I'm interested in trying, but haven't really taken much out so far (and didn't see anything worth noting for what I did).

Prochargedmopar - I don't have any exhaust volumes. An unported intake w/ big guide bosses was 195 cc. After Dwayne's porting, the two ports I measured were 205-207 cc w/o the RB adapter plates. With the plates on the extra 3/4"+ runner length increased the volume around 30 cc, IIRC. I haven't bothered measuring the one port I've fiddled with so far.

Also, the PRH ports didn't appear to "find" any more CFM when tested at 28" than at 10", given the difference between my bench and a local SF-600's results were only about 5 cfm. That little change could be attributed to normal variation between benches, not the test pressure difference.

==========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

Yes I'd forgotten about the roof limitations in the big block heads, most of my experimental is with small block.

(weld the the roof some & raise it)

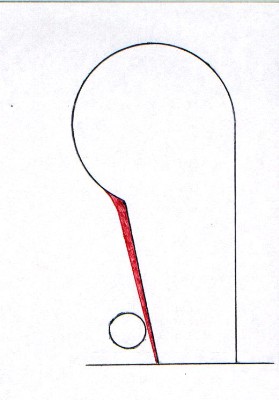

Anyway I'll put this picture in to show what I do in the production small block runner wall, I start with the pinch slightly because it's not very thick there & gradually take more as it gets closer to the bowl area, the picture is approximate but just gives a little bit of an idea.

This type of grinding does seem to really wake up the mid range where the cam lobe spends a great deal of it's time.

As you know the flow bench is only a tool but a useful one even though other factors can't show on the flow bench like, air density, thermal transfer from the engine to incoming charge, mass of fuel, piston design, stroke / rod ratio, piston speed, engine rpm, intake manifold tuning, blah, blah, blah...

===========================================

jyrki

Moparts Member

Posts: 1717

From: Vantaa, Finland

Registered: Nov 1999

posted 08-09-2002 01:50 AM

..and like I said earlier my hogged out Stage VI's have 220 cc intakes, they were about 190cc untouched.

===========================================

Prochargedmopar

Moparts Member

Posts: 1477

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 08-09-2002 02:55 PM

Nice pic Fast One.

So far I havn't touched the inside wall other than smoothing it out. This makes sense though. Kinda like "laying back" the short turn on the floor if I understand correctly. Wish I had a sonic tester!

==========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

posted 08-09-2002 09:24 PM

On the earlier heads the pushrod wall side usually is quite generous in thickness, up to 6 mm or .234 in

=========================================

Brad H

Moparts Member

Posts: 2105

From: Washington, D.C., metro area

Registered: Nov 1999

posted 08-11-2002 11:50 AM

Brief update. Based on the feedback I'd received on the intake port, I went back into it and carved on it some more. I have to admit that I broke the first rule of testing and did a bunch of minor(?) changes at once because of time constraints. That said, what was done included...

- Opened pushrod pinch to 1.15"

- Removed "a little" from pinch to bowl entry on long wall

- Dropped floor more from pinch to short turn

- Blended short turn into dropped floor

- Opened bowl entry between guide and wall on short wall

- Removed "a little" from roof between pinch and base of guide

Intake

lift---befr--/after

.100--68.5 / 69.0

.200-147.3 / 146.4

.300-214.4 / 214.4

.400-251.5 / 253.1

.500-277.6 / 281.2

.600-288.3 / 295.4

.700-297.2 / 305.2

.800-304.3 / 311.5

This seemed a step in the right direction (at least for offsetting what I may have done wrong).

The exhaust port got the following:

- Dropped bore-side wall down more straight from seat (less bias)

- Dropped outside wall down more straight from seat (less venturi)

- Opened bowl area behind guide boss where machined ridge was left fom MP's seat cutter

- Widened channels on both sides of guide boss

- Narrowed guide boss

- Raised roof slightly (approx. 1 mm) and straightened walls some leading from bowl to exit

- Additional profiling of short turn.

Exhaust w/o tube

lift---befr--/after

.100--55.8 / 54.7

.200-108.4 / 107.0

.300-153.6 / 145.5

.400-179.0 / 174.7

.500-198.3 / 197.6

.600-209.1 / 214.4

.700-215.3 / 228.3

Exhaust with tube

lift---befr--/after

.100--56.8 / 57.1

.200-113.2 / 111.3

.300-156.4 / 151.8

.400-191.0 / 185.5

.500-215.1 / 210.8

.600-230.8 / 230.8

.700-241.9 / 248.3

Looks like this was a step backwards everywhere but .600+". Oh, well...

===========================================

fast68plymouth

Moparts Member

Posts: 3354

From: so burlington,vt usa

Registered: Aug 2000

posted 08-11-2002 08:01 PM

its funny how certain people have a knack for certain types of ports.

ive always been able to get pretty good numbers from stage VI heads.

the shape just seems to "make sense" to me.

i basically dont try to change the basic shape of the port very much at all....i just remove the surplus material from the guide bosses, and make everything else a bit bigger.

on the other hand, i really struggle to get the big numbers out of Indy SR's. its all in the sort turn on those(for me anyway).

i do the basic guide and bowl work, then make my first attempt at the short turn.

i'll test it then, and always have to go back at least once more. and sometimes its several times more.

on my own SR's, i was working one port over, and just couldnt get the big numbers at .600+, and the last attempt had actually resulted in a slight loss of flow.

i know from experience that when that happens....just move to the next port before you really screw it up.

after i had done a couple of the other ports, and was satisfied with their numbers, i made one last very small change in that first ports floor....and wha-la!!

i find the SR intake short turns to be very tempermental...and since they vary in shape a fair amount as-cast, what works in one port, may not work in the one next to it.

by comparison, i can remove all the material i need to on an older stage VI buide boss in waaaay less time than i have in an SR short turn, and up to this point anyway, ive had a really easy time of it with regard to the stage VI intake short turns.

==========================================

Fast One

Moparts Member

Posts: 3765

From: Australia

Registered: Nov 2000

posted 08-11-2002 08:57 PM

Ha, yeah been down that road before, did the usual porting thinking this will be good & it ends up not doing what it should in theory.

Well the intake hasn't really lost anything down lower but made some gain up top, I'd guess you're a bit happier now.

As for the exhaust, hmm, minor loss in the lower lift, opening the width of the runner might improve that but maybe you shouldn't tempt fate, your heads though.

I found some figures from a set of 915J heads I did, probably the best I got so far without welding, I'll include some figures from a welded exhaust, both figures are with 1.60 SpeedPro nail head exhaust stainless.

Unwelded 915J maximum porting.

lift/cfm

.100/55

.200/107

.300/144

.400/170

.500/186

.600/198

.650/198

Welded 915J exhaust

lift/cfm

.100/54

.200/106

.300/147

.400/173

.500/192

.600/202

.650/205

Notice that there's no great improvement between .200 - .400 lift, how ever the air traffic has moved up higher with good results.

But now here's some results with just swapping over to Tulip valve in the exhaust, no extra porting & same head

lift/cfm

.100/60

.200/115

.300/157

.400/182

.500/198

.600/205

.650/208

Interesting eh!, just swapping the valve design made good changes all through the lift range.

Tech Index