Moparts Tech Archive

Big Block

Crank Q's and I.D.

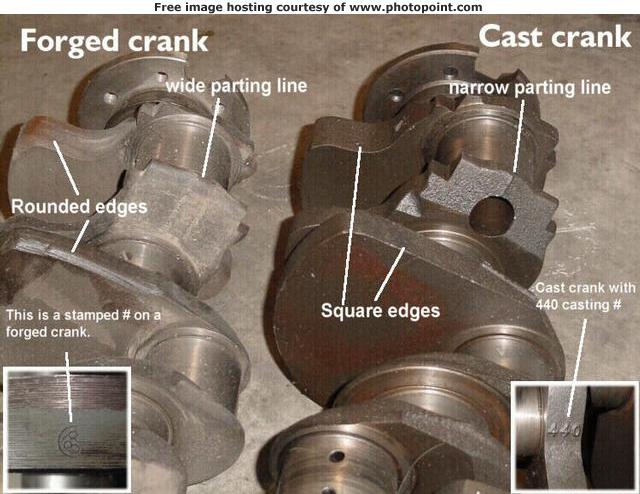

Crankshaft photo for tech archiveMichael Doty

This is a photo I put together to aid in the positive identification of cast and forged cranks. Hopefully the illustration will be more definate than a text only description.

=======================================

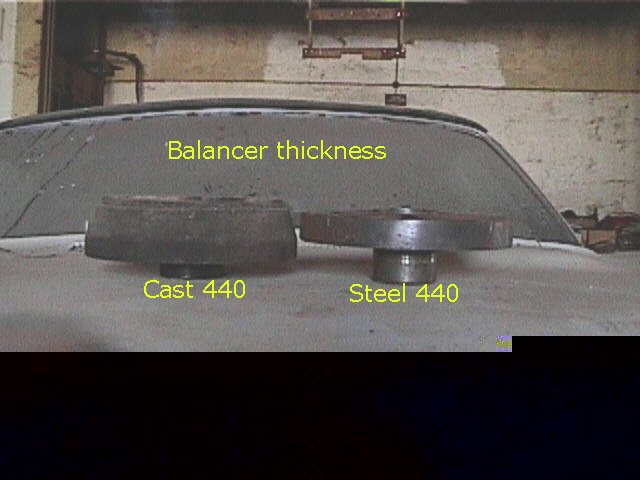

Heres a pic of the bal for the steel and cast crank 440's.

Pic donated by C-body.

=======================================

Drilled Crankshaft Journal Question

451 Jim

Moparts Member

Posts: 2585

From: Lexington Park Maryland

Registered: Dec 2000

I have 5 forged steel, 3.75" stroke, big block crankshafts sitting in front of me. The 3 that are known 440 cranks have a 1" hole drilled in the 1st and last journal about 2.8" deep, ie not all the way through.

The one that is claimed to be a 413 crank has the holes drilled all the way through, and the counterweights don't seem to be as long (degrees around the crank), and it has some "wings" on the 2nd and 3rd journals.

The last one is unknown, but could be a 426 wedge crank. The counter weights seem the same as the 440, but the 1" hole is drilled all the way through.

Can anyone shed some light on this?

=======================================

joe z

Moparts Member

Posts: 789

From: Drums, Pa

Registered: Nov 1999

posted 11-04-2002 10:00 PM

nice collection you have there jim. just to add, i have a 413 crank that has through holes on the first and last journals. and it did have "wings" i got holes drilled in the other 2 journals and lightened all the rod throws.

======================================

jamesc

Moparts Member

Posts: 3975

From: Peoples Republic of New Jersey

Registered: May 2001

posted 11-05-2002 02:39 AM

a friend of mine has a 440 with the heavy rods (don't know if it's HP,6 pak, MH or what) and it has the litle wings on the crank.

edit: as for the lighting holes i've seen em both ways, doesn't seem to be any rhyme or reason

======================================

JohnRR

Moparts

Posts: 10731

From: Ma.

Registered: Nov 1999

posted 11-05-2002 01:15 PM

jim , how many hours was the crank in the machine ? my shop had my MP crank that i got from mancini in the lathe for 10 hours to cut it down , the counterweights started at 7.5ish

=======================================

451boy

Moparts Member

Posts: 5298

From: Oregon

Registered: Nov 1999

posted 11-16-2002 10:30 PM

Nice collection of cranks! I have both 413 adn 426W cranks and they all have the little wings. Which I believe are actually forging sprues but I'm not positive.

I turn the counterweights on an old Graziano lathe. Gear driven. I use a carbide inserted tool. It takes me about one hour to turn a crank down to 7.250 diameter. That includes setup and teardown. With a nice rigid setup (I have a fixture that bolts to the crank flange and mounts in a three jaw chuck) you can take a big bite and let the power feed do the work.

=======================================

mark gates

Moparts Member

Posts: 1886

From: cambridge vt.

Registered: Jul 2001

posted 11-17-2002 05:29 AM

My 1960 383 8-bolt crank has wings as well

=======================================

451 Jim

Moparts Member

Posts: 2585

From: Lexington Park Maryland

Registered: Dec 2000

posted 11-17-2002 10:57 AM

451 boy, Wow, only 1 hour; you are the man! I agree getting a good ridgid setup is the key, I haven't pushed it too hard so it takes me longer than that. And I also spend 20 minutes or so putting 1/8" chamfers around the #2 and #4 bearing positions for extra clearance. 10 hrs was crazy.

=========================================

4.25" stroke cranks?

moparnutz

New Member

Posts: 27

From: redmond

Registered: Dec 2002

posted 01-11-2003 04:04 AM

Who sells 'em?

What can I expect to pay?

I'm looking at maybe a 510 CID big block, but I'm curious as to where I can find a stroker crank for it. So far, I've found a couple, but I can't get pricing info 'till monday, and this is running around in my head nonstop.

Thanks!!

-Bill

==================================

65Belved

Moparts Member

Posts: 1576

From: Gun Country Tucson AZ

Registered: Jul 2000

posted 01-11-2003 09:04 AM

I don't think this will help much but at least I will bump the thread back up for you.

I have a 4.25 crank in my engine a 511ci.

I bought it back in 97/98, actually it is a welded up crank. I sent a stock crank to Pauls Crankshaft Srvice in Texas and he welded it and reground it to 4.25.

I had it done for about $600.00. It looked lke a work of art when I received it.

Paul is the guy that Hughes and Muscle Motors were getting their 4.25 cranks from to sell.

There are a few guys here on Moparts that have a crank from Pauls, I think streetwise is one of them.

=====================================

DusterDave

Moparts Member

Posts: 4070

From: Tampa, FL

Registered: Mar 2000

posted 01-11-2003 09:16 AM

Another idea is to buy an Eagle 4.150 crank and have it offset ground and end up with a BB Chevy size journal.

==================================

MRMOPAR

Moparts Member

Posts: 1751

From: Tucson, AZ

Registered: Jan 2000

posted 01-11-2003 09:37 AM

Fuel motor cranks do not have a flex plate/flywheel mount the same as a 383/440 crankshaft. Why is that?? The fuel cranks use a mount going back to the old 392 hemi engines. When they switched to the later himi a lot of the teams had the old hardware, so the cranks were and continue to be made with that mount style. A register ring will have to be installed on the crank, and then end will most likely have to be counterbored for the converter hub. This can be done by several of the crank mfgs but will add to the cost of the crank.

=====================================

v8440

Moparts Member

Posts: 610

From: Montgomery, AL

Registered: Jun 2002

posted 01-11-2003 11:06 AM

Better get it magnafluxed. I've had 4 cranks of that type, and all of them were cracked. Only one had cracks that weren't fatal. Oh, and these were all alcohol motor cranks, far easier on them than fuel.

=====================================

Streetwize

Moparts Member

Posts: 1604

From: Charlotte,NC USA

Registered: Dec 2000

posted 01-11-2003 11:11 AM

I also got a 4.25"/2.00"BBC journal Welded stroker from Paul Savadin at Paul's crank shop. It is a work of art, his machining and attention to detail is second to none. The 4.25" is actually stronger and lighter than the 4.15"/2.375" and required LESS welded material to finish. Paul's cranks were also indexed and precision phased as part of his machining, far beyond factory specs.

Paul did cranks for some guy named ...Don Garlits (???) , I guess that's a pretty good endorsement of his handiwork.

Paul was very ill the last time we spoke and I have been unable to reach him in over a year. DRAM's friend Larry down in Fla does excellent machine work and is a friend of Pauls's, but I can't remember his shop name off-hand. Forged cranks should all be drilled for pilot bushings and have STD 6 bolt flanges.

Wize

=====================================

4x4 440

Moparts Member

Posts: 1414

From: Glenmoore,PA,US

Registered: Jun 2001

Crower forged #95166 is $2000.00 plus balance or a billet for $2700.00 plus balance. I think both are 8 bolt Hemi flange and 2 keyway snout for blower applications. www.crower.com and www.callies.com are some places if you want stock Mopar size journal with no welding. Beware of the prices.

===================================

rrsbdh

Moparts Member

Posts: 2890

From: Decatur Alabama

Registered: Oct 2001

posted 01-12-2003 02:39 AM

Indy has one for 1300 and Ohio has one too for 900. I would like to have one but I don't have any other info.

==================================

will a 4.500 stroke crank fit in a 440 block?

MoparTony

Moparts Member

Posts: 2121

From: Detroit area

Registered: Jul 2000

posted 01-15-2003 03:07 PM

If so what are the mods needed.

==================================

v8440

Moparts Member

Posts: 610

From: Montgomery, AL

Registered: Jun 2002

posted 01-15-2003 03:10 PM

I believe it can be made to work if you go to an external oil pickup (a stock style pickup gets hit by the crank at that kind of stroke), but I wouldn't do it. At the power levels that sort of thing can generate, you're really asking for trouble with a stock block. I'd much sooner do a 3.915 or 4.15" stroke in either a 440 or a 400 block, preferably a 400 block.

If it won't have to be crazy, then go with the 400 block and the small crank. You'll be able to make plenty of power with that, and won't have to worry about the block as much. The 400 block can take more power than the 440. So, why go to the trouble to shoehorn in a 4.5" stroke crank into a weaker block so you can make the same or less power and have somewhat of a hand grenade to boot? Seems like a lot of money to do essentially nothing.

======================================

Tech Index