Moparts Tech Archive

Big Block

BB E-Head Testing Results

Here are the results of fast68plymouth's testing of the BB E-heads.All the testing and results listed here are from fast68 (Dwayne Porter).

We would like to Thank him for his efforts and willingness to share the info with the board members.

The graphs and pics in this thread have been provided by 451 Jim. Thank you Jim

carl

----------------------------------------------

Well, the testing is over, so its time for some results.

The premise was to see how easily the new E heads would make 600hp on a 440 based motor, and how they compared to a decent set of ported iron heads.

This is a logical test in that many who have ported iron heads will have them fail, and these are a true bolt on head, with the only possible parts required for the swap being some head bolts with a smaller hex.

I built what i felt would be a typical bracket type short block for the test, and used very generic parts. also, no "special tricks" were done in the prep. just std race type machining practices.

The block was line honed, decked for "0" piston height, bored, honed with plates using 220, 280, 400 stones, and a final surface prep using plateau brushes.

when done in this manner, the bores are actually shiney, and if you stick your hand in the bores, you can see the reflection of your hand in the walls.

The only oiling mod was to install a 1/2" pick-up. The new hole for the 1/2" pick-up was blended to the original hole with a small burr and a die grinder.

The parts used were as follows:

-oe steel crank, 10/10, balanced

-1968 block

-SRP flat top pistons

-JE rings, std tension oil ring, 1/16, 1/16

compression rings

-Eagle rods

-Crower main studs

-Federal Mogul main and rod bearings, race type

-Rollmaster billet timing set

-UD roller cam, 290/295, 259/264, .651/.651 w/1.5(.434 lobe lift)

-Herbert roller lifters

-Comp bronze gear pressed on to oe shaft

-Milodon low profile pan and louvered windage tray

-Melling HV pump

The short block went together nicely.

main clearance was .003, rods .0025.

cam in at 105.5, cam thrust set at about .010.

deck clearance basically right at zero.

We are now ready for some heads.

Chapter 2 of Dwayne's report.

----------------------------------------------

I'm not going to go through all the details of the head prep here. if you need to see it, its all in the tech archives.

The oe heads are 2 different heads from 2 different motors. Two brothers who have S/G cars were running iron heads, and each had one crack and went to aluminum heads.

I originally ported both heads. one set had 2.18 intake valves, the other 2.14.

I took all the parts from the 2.18 heads, and used them in both heads. which meant I had to enlarge the seat to 2.18, then machine the bowl, and blend the porting into the new seat location to make them a "pair" of heads.

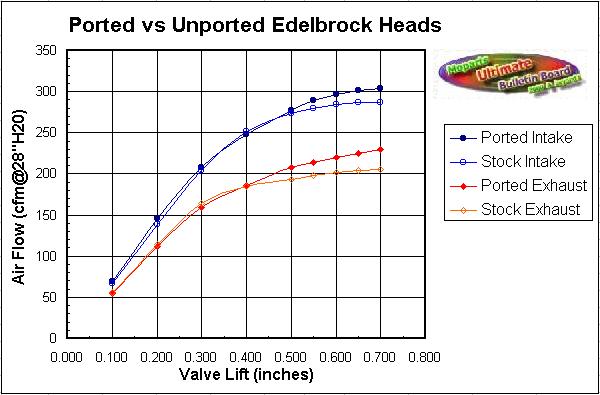

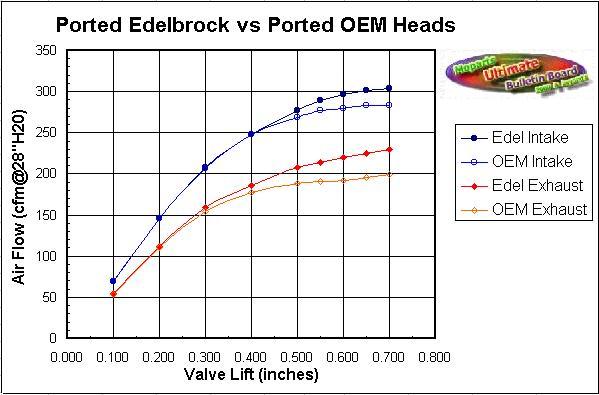

Here are some flow numbers from these heads. this is an average of one cylinder from each head, but they were very close to one another all the way up.

Also, the flow numbers for the e heads, an average of all eight cylinders. the E heads proved to be inconsistant from port to port, but ech head was close to the other head in a port by port comparison. for example the ports for numbers 1 and 8 cylinders flowed almost exactly the same, as did 3 and 6, 5 and 4, and 7 and 2.

After closely looking at the ports knowing this, you can see how they dont all seem exactly the same.

Getting them all the same might be a chore.

Since these arent realy "race heads" I was reluctant to take huge amounts of metal out of any part of the port for fear of breaking through. But rather i did the same thing to each port, so they more or less retain their original differences from port to port.

lift----E in/ex-----oe in/ex

.100----69.0/54.1----69.3/54.0

.200---145.6/112.3--145.3/110.3

.300---207.3/159.0--207.0/154.6

.400---247.8/186.5--247.8/177.2

.500---277.2/207.7--268.8/188.1

.550---288.9/214.4--276.9/191.4

.600---296.8/220.5--280.1/192.3

.650---301.5/225.3--283.2/195.6

.700---304.3/230.1--283.2-199.8

As you can see the ported oe head with the 2.18 intake valve stays with the E head through .400 lift, then the extra port volume and better short turn start to pay off.

The exhaust ports on the iron heads aren't as good as some more recent ones I've done, but these heads were both on cars running well into the 9's with only solid lifter cams and moderate compression.

IMO, These are typical of what most ported iron heads are capable of, and are a good representaion of what most people have for "fully ported" iron heads.

These heads flowed as well on the intake side as any ported oe iron heads(non-MW) that ive had on my bench.

Yes, There will be some that are better, but I dont think thats the norm.

Chapter 3

-----------------------------------------------

The short block and heads are done. It's time to see how it all fits together.

I had a few intakes on hand, So I mocked everything up with both the oe heads and the E heads.

Fortunately the pusrods fit both sets of heads, and few intakes without needing any more milling.

The oe heads were 78cc's, The E heads 74cc's. The CR with the iron heads is 11:1, with the E heads it's 11.5:1. Not quite the full point they recommend for the switch from iron to aluminum, but again representative of what the typical bracket engine might have. The iron heads were cut about .060 as near as I could tell, and the E heads I cut .040, on both the intake and deck surface.

The valve springs are K-Motion K-1100's, which are a mild silicone type 1.550 dual spring, and they were set up at 1.900, which was 210ish closed. open pressure is a little over 500lbs.

As it turned out the Harland Sharp 1.5 roller rockers ended up being more like 1.55. so, The net lift at the valve using a checking spring was .655. V/P clearance with this cam and pistons was .088 exhaust, and .075 intake and the E heads. a little close to use in a car, but okay for the dyno. The oe heads had about .010-.015 more on both valves.

The test between the 2 heads is going to be done with an M1 intake, 4150 type, and 2 different carbs. a modified 850 annular Holley(905cfm) on a phenolic 1" open spacer, and an out of the box HP1050, #8896 on a Moroso adapter plate.

Also, The dyno headers will be used for all tests, which are 2-2 1/8 primary tubes into 4" collectors.

Sunoco Standard purple race fuel will be used for all tests as well. This is 110 octane, I believe, and is good for motors into the 13.5-14:1 range.

The motor was put on the dyno with the iron heads, and the M1 with the 850 carb, and broken in for about 20 mins before any pulls were done to seat the rings and check for leaks and set the timing.

The timing was set at 36degrees. I have dynoed many 440 type motors and can tell you that on a motor like this there is no magic in the timing. Moving the timing anywhere in the 33-38deg range has little affect on power.

I set it at 36, and left it there for all the tests. In fact, The distributor wasn't moved or removed for the head swap.

After some warm up pulls to get some temperature in the oil, this is what kind of numbers I got.

rpm--850/tq/hp----tq/hp/1050

4000----459/350--453/345

4100----508/396--488/381

4200----520/416--504/403

4300----531/434--519/425

4400----539/452--532/445

4500----543/466--537/460

4600----542/475--535/469

4700----542/485--539/483

4800----542/495--537/491

4900----540/503--537/502

5000----540/514--536/510

5100----540/524--538/522

5200----533/528--534/529

5300----535/540--530/535

5400----529/544--528/543

5500----524/549--522/547

5600----519/554--514/548

5700----518/562--512/556

5800----514/568--511/565

5900----510/573--509/572

6000----508/580--502/574

6100----503/584--497/577

6200----493/582--491/579

6300----487/584--482/577

6400----473/577--472/575

6500----473/585--465/576

6600----462/580--458/576

6700----454/579--447/570

6800----440/569--440/569

6900----426/560--425/558

7000----422/562--425/566

As you can see, on this particular combination the extra cfm of the bigger carb isn't really worth anything.

In fact it's a little down on power. I made several pulls with each combo, the 850 would make mid-580's every pull, the 1050 never once made even one 580.

This is about what I was looking for out of the motor with thse heads and cam, so no suprises. It did what it should have done.

Next step...the new heads.

Chapter 4

-----------------------------------------------

Now, We have a baseline test and now its time for the head swap.

The swap was a breeze, and everything just bolted right up.

The valves were set, and the M1 re-installed with the 850 carb and the motor was fired up and brought up to temperature.

A quick check for leaks and we were ready to go.

I made a few pulls to get back some heat in the oil. I didnt have a temp sender in the pan, so to get some degree of consistency I was watching the oil pressure. as it gets hotter the pressure drops a little. Not as accurate at all as the temp sender, but at least you know the temps are in the ballpark.

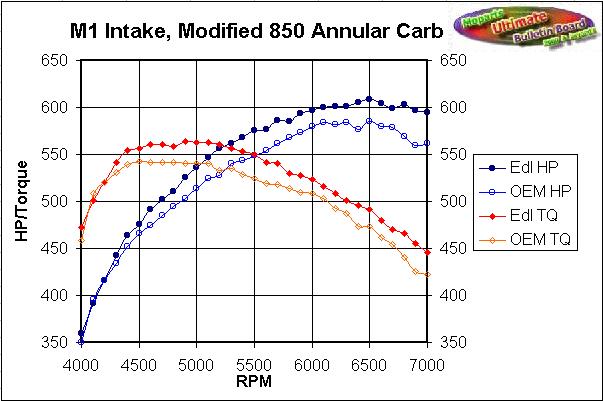

After a few runs with the 850, I again tried the 1050 on the adapter. Here is what I got:

rpm--850/tq/hp----tq/hp/1050

4000----472/360--478/364

4100----501/391--520/406

4200----520/416--541/433

4300----541/443--552/452

4400----554/464--557/466

4500----556/476--561/481

4600----561/491--564/494

4700----561/502--566/506

4800----559/511--566/517

4900----564/526--564/526

5000----563/536--565/537

5100----563/547--560/544

5200----561/556--558/553

5300----556/562--554/560

5400----553/568--546/562

5500----550/576--545/571

5600----541/577--541/577

5700----540/586--535/581

5800----530/585--535/591

5900----528/594--532/596

6000----523/597--526/601

6100----516/600--518/601

6200----509/601--512/604

6300----501/601--504/604

6400----496/605--498/606

6500----491/608--490/606

6600----480/604--482/606

6700----470/599--475/606

6800----466/603--467/604

6900----455/597--457/600

7000----446/595--450/599

For me the important thing with these heads was to see how easily they would make 600hp. Since thats achievable with iron heads, These needed to easily be able to make that mark to be worthwhile, IMO.

I had originally planned on using a cam with more duration, and even had it all degreed in the short block, but then discovered inadequate V/P clearance and had to use this smaller cam. I'm sure the other cam would have yielded about 10-15 more HP, but might have cost a few lbs of torque.

This is a VERY mild engine combo for 600hp, and idles right down to 900rpm, and is smoother at idle than a MP509 cam by quite a bit.

By these numbers, The E-heads with similar port work to iron heads are worth about 22hp more, And an equal gain in tq. however, I think with more cam the difference would have been greater.

Also note that with the new heads the 1050 carb starts to show some promise, Another indicator that a bigger cam would start to pay dividends in power.

The next step? lets swap some intakes!!

Chapter 5

-----------------------------------------------

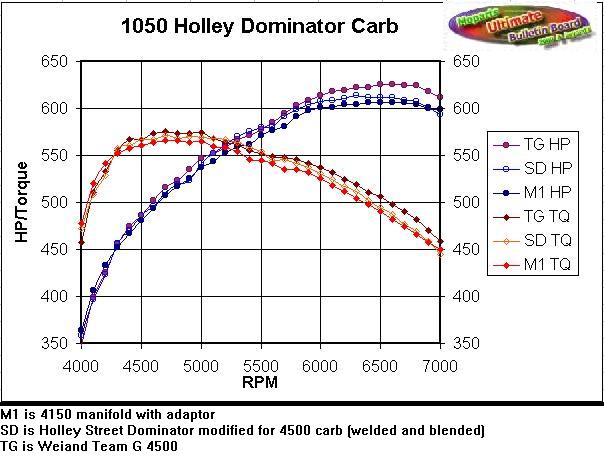

After the baseline testing was done it was time to swap a few intakes and see how they measure up. I was particularly interested in comparing the TeamG 4500 with the M1/adapter combo. There always seems to be some debate as to which one is better for a "moderate" bracket motor....which this definately is.

again, I would have liked to have more cam in the motor for this test, But you have to test it with what will fit.

I also have an old Holley SD that I made into a 4500 type intake long before anyone offered one for the BB mopar. Everyone I've ever showed it to who is supposed to be "in the know' about intakes says it wouldnt work very well. I knew it worked at least reasonably well as I had tested it on the dyno and in a few race cars and it always seemed to work okay. but, The teamG 4500, and the M1 4150/adapter combo are supposed to both be superior. We would now find out. After I had tested those, I decided to try the Weiand TR with 2X650 Speed Demon carbs I had as well.

Several runs were made with each intake. The carb was untouched between all the tests, the only change being the intake itself, except for the TR test.

I have sent a few pics of the Holley intake to 451Jim to see if he can post them.

To keep from having to go to the Part4 thread I will include the numbers from the M1/adapter here.

rpm--M1/tq/hp--SD/tq/hp--TG/tq/hp--TR/tq/hp

4000---478/364---472/359---457/348---496/377

4100---520/406---508/397---511/399---532/416

4200---541/433---529/423---533/426---546/437

4300---552/452---557/456---555/455---569/466

4400---557/467---561/470---567/475---574/481

4500---561/481---567/486---567/486---584/501

4600---564/494---567/496---573/502---591/518

4700---566/507---571/511---576/516---597/534

4800---566/517---568/519---573/523---597/546

4900---564/526---570/523---573/535---591/551

5000---565/537---569/542---574/547---594/565

5100---560/544---568/552---568/552---583/566

5200---558/553---567/562---564/559---578/572

5300---554/560---564/570---562/567---574/579

5400---546/562---559/576---555/571---570/586

5500---545/571---554/580---552/578---564/591

5600---541/577---545/581---549/585---561/598

5700---535/581---546/592---548/595---553/600

5800---535/591---542/599---546/603---550/607

5900---532/598---537/604---541/608---546/613

6000---526/601---531/607---537/614---544/621

6100---518/601---524/608---532/618---534/621

6200---512/604---517/611---524/619---537/634

6300---504/604---512/614---519/622---533/639

6400---498/606---502/612---511/622---523/637

6500---490/606---495/612---506/626---515/638

6600---482/606---487/612---498/626---504/634

6700---475/606---477/608---490/625---491/626

6800---466/604---469/607---482/624---472/612

6900---457/600---458/601---470/618---452/594

7000---450/599---445/594---459/612---429/572

As you can see, The TeamG 4500 is the best of the single 4bbl intakes for a 600hp+ motor, and that my old Holley isnt that bad at all. And of course, The MP part isnt all its cracked up to be.

Also the TR makes the most tq by far, but has some pulse timing issues at the top end of the range, and just noses over above 6700rpm.

I have run this intake on another motor that had a bigger cam and more compression and it did the same thing, only it made 30hp more than a TeamG on that motor.

So, It sure looks like the easy S/ST, S/G combo is the E-heads, a mild roller, and a TeamG with a 1050.

I'm sure that with the heads milled to get closer to 12:1, and pistons that will acomodate a cam in the mid-270's @.050 that you would have a 650hp combination.

Keep in mind that the carb, and the M1 and TeamG are unmodified, so these results would very easily be duplicated.

Also, I have ported dozens of sets of oe iron 440 heads, and the set used for this comparison is a pretty good set. It was the first set of E-heads I have ported, so I'm sure there is some more to be had out of them, and in time I'll find a way to unlock more flow.

Simply put, They are a bargain.

Now if they can just get that new Victor intake out.....

The pictures below are of the modified (to accept a 4500 flange Holley carb) Street Dominator Holley intake used by fast68 on this test.

Chapter 6

------------------------------------------------

We now have a bunch of numbers and info to look at and mull over. But what does it all mean to the average person looking for an upgrade. or, How do these numbers equate to on-track performance.

It's been my experience that dyno results can, and usually do vary quite a bit from dyno to dyno. much worse that flow bench results.

I have seen personally the numbers vary by 11%, and on that particular 632 big Chief motor it was to the tune of about 115hp.

and on one of my own motors I saw the numbers vary by almost 70hp. So these differences can be very real, and make it nearly impossible(in my mind at least) to quantify the results unless you know some "history" of the dyno. What I mean by that is, what kinds of numbers equal what kinds of times.

I'm going to give you a few examples of what some of the motors from our dyno have made for power, and what they run in the cars they are in. This should give you some idea as to what kind of performance potential this motor with the E-heads, and these various intakes would be capable of.

3900lb 68 Charger, 446, 625hp/585tq, 5000stall, 4.56's-best of 10.46/131+

3650lb Satellite, 448, 555hp/545tq, 5300 stall, 4.56's-best of 10.65/129+

70 Cuda back half car 3150lbs, 446, 606hp/550tq,5000stall, 4.88's-best of 10.13/133+

70 cuda S/G car 2500lbs, 452, 650hp/565tq,

5200stall, 4.88's-best of 9.31/145

29 Ford roadster S/G car 2200lbs, 493 Mopar, 695hp/620tq, 5000stall, 4.30's-best 8.91/150+

70 Challenger RT/SE 3800lbs(?), 446, 445hp/480tq, TA "tight" 10", 3.91's- best of 12.34/111+

79 Cordoba 3850lbs, 366, 455hp/438tq, 4900 stall, 4.56's-best of 11.95/113+

And a few other non-Mopar examples:

1400lb dragster w/ 525hp would run an average ET of 8.40

3000lb 55 Chevy S/G car, 795hp ran 8.80's.

1600lb dragster w/ 780hp runs 7.70's.

2500lb Monte Carlo S/G type 4-link car with a 910hp single carb 632 runs 8.10's

Whats next? Well since I have a mule motor all done, and a set of SR's on hand.....When I find the time to finish these heads, I'll put them on this motor and see how they compare.

Then it will be a cam swap, and finally a set of stage VI/MW heads that will end up staying on that short block....provided they make decent power

Lastly, I'd like to apologize for the delay in getting this all wrapped up to all those who contributed. Hopefully there is enough info here so that you feel it was somewhat worth the wait.

I'd also like to thank 440/451Jim for his help with the charts and graphs, and for posting the intake pics.

All in all I think the results were positive, and its sure that Edelbrock has a winner in the new heads for the BB Mopar enthusiast.

I can tell you that I will be recommending these heads to anyone who can use them for their combination.

As i said in the begining...two thumbs up.

Tech Index