Moparts Tech Archive

Manual & Clutches

CHEAP Tremec 600 installation pics

From - 446acuda

A few things to note when looking at pictures.This is a '69 440 Barracuda. The major upper crossmember hacking wouldn't be necessary on E and later B bodies. I've heard that there are issues on early B-bodies.

I didn't want to cut the transmission to fit under the stock loop so I cut the loop out and replaced it with a boxed loop--no big deal on this since it was 318,auto, 7.25 originally but might be a big deal on 340 car etc so the Keisler set is the way to go if you don't want to hack up a valuable car.

Note on driver's side bottom I used upper hole since lower hole is almost off of the bellhousing. Also shifter is made by Pro 5.0 since stock left a lot to be desired. TKO-500 and 600 take a different shifter than the previous Tremecs and TKOs and the only companies that make these shifters is Steeda and Pro5.0.

Trans mount is Energy suspension typical GM mount but any old part store mount could be used.

Slip yoke is MW but any junkyard 31 spline ford yoke can be used i.e. C6, toploader and some AOD's. I'm using a Ram 6-paddle metallic disc but any GM 26-spline disc can be used just get the same size as you had.

On the throwout bearing pics from left to right is Jeep/new dodge throwout bearing, 18-spline hemi trans bearing in the middle and 23-spline throwout bearing on right.

My trans was used out of the box with the exception of cutting the front bearing retainer down from 4.850 to 4.80XX. no modification were made to the input shaft. p/n's are Napa N4093 for throwout bearing('97 4.0 Jeep Wrangler application and many later Dodge trucks), pilot bearing is Napa B65174('95 Mustang GT), Mopar 4338876(the one that fits in torque converter hub but has bronze bushing instead of bearing) Use bearing from B65174 and disgard outer housing and use housing from 4338876 and disgard bronze bushing.I spaced the bearing assy. rearward with big .125" thick washer to ensure that it had full contact with bearing surface on input shaft.

Trans is P/N 5008(Ford application) Last, try not to look at the nice wiring in the car, among other things.

Cost: about $2000, $1600 for trans.

throwout bearings-notice that 23 spline bearing and Jeep/new Dodge bearing have almost same face surface area so there doesn't seem to be a need for the big surface area on the 18-spline bearing. Also the Jeep bearing has the largest I.D. about .012" larger than 18-spline bearing

Mine is also a Lakewood scattershield that I bought used years ago. I came out of a Big Block Arrow . Fork is a typical big block short fork. The hole in the bellhousing is still 4.80" so I could bolt an A-833 back in here by changing the disc, throwout bearing, pilot bearing and driveshaft. The only modification to the bellhousing is to redrill it and weld nuts inside for the Tremec pattern. The ONLY work that I had to farm out on my swap was to get the Tremec bearing retainer turned down from 4.850 to 4.806" or so. EVERYTHING else in over-the-counter parts store stuff.

I went from a 3.73 with the 4-spd to 4.56 with the 5-spd. I figured if I'm going to have that much overdrive I'm going to make it worth it. Cruise RPM dropped from 3500 or so down to less than 3000. 60' time dropped real nice and are consistent too thanks to more gear letting me run taller slicks(28' vs 26') without bogging off the line. Low 1.6 are the norm and was pulling 1.53 when the slicks were new. I wish I had as much good things to say about the top end charge.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Tremec A-body trans x-member pics and dimensions

Here are some close up pixs of homemade trans x-member for Tremec TKO-500 and 600 and possibly others.

--These pics apply to '67-up A-bodies SB or BB using Lakewood scattershield.

--Don't use these cartoon drawing as blueprints-use as a guide only

--this crossmember is for a GM-style mount

--IMO

the best way to do this would be to have a driveshaft ready before you

start, put car on jackstands, unload torsion bars, cut floor and loop,

weld new squared loop in so that trans will fit up in there, reload

torsion bars and put jack stands under lower control arms and rear axle

housing, install driveshaft and get angle correct and then take

measurement as shown in this attachment instead of going with the 1

1/8" dimension that I have shown in the crossmember side view

attachment. Like I said use all this as a guide only and do it YOUR way.

With

the A-833 in my car I had a '73-up spool type trans mount/crossmember

so it was easier for me to make a totally new crossmember but if you

have a '67-72 block type mount then it MIGHT be easier to modify that

crossmember and save yourself some work.

A=1-1/8" from centerline of inner holes to where mount would sit inside x-member

A=approx. 2 3/8" or whatever your stock x-member was. B=2 3/4" C=3-1/4". notched area is to the rear for mount clearance.

A=1.5" B=1-5/8" C=3-3/8"very approximate. This is from the bottom looking up. note pass side and dr side. Holes are 7/16" clearance holes ( approximately 0.470")

floor cut dimensions. A-D are side to side, door to door dimensions with measurements on each side of trans centerline. i.e. A=3.75/4.25 means 3.75 on driver's side and 4.25" on passenger's side of centerline. These are straight measurements and don't take into account the curve of the floor. dimensions E-H are from the FACE OF THE SCATTERSHIELD REARWARD.Also note that passenger side floor is bent out quite a bit to get square support in there and the dimensions are for after this was installed. It might be better to go by the pics instead on the pass side. A=3.75/4.25 B=5/5.5 C=5.25/5.25 D=2.5/2.5 E=2" F=5 G=13-5/8, H=22. the 833 is where the 833 shifter used to be.

square hoop dimensions A=7" B=1-1/4" C=8" A is from bolt hole centerline to inner top

--------------------------------

Well you showed us yours, I'll show you mine. -- CJK440

My E required the crossmember be pretty much removed as the shifter was positioned directly smack dab under it. You could flip the shifter around and move it forward a few inches but that doesn't really help since the "boss" still colided with the arch.

I toyed with the idea of making a permanent arch to replace the piece I cut out but it seemed easier and more straight forward to go the bolt in x-member route.

So without further adeu for the E-body guys.......

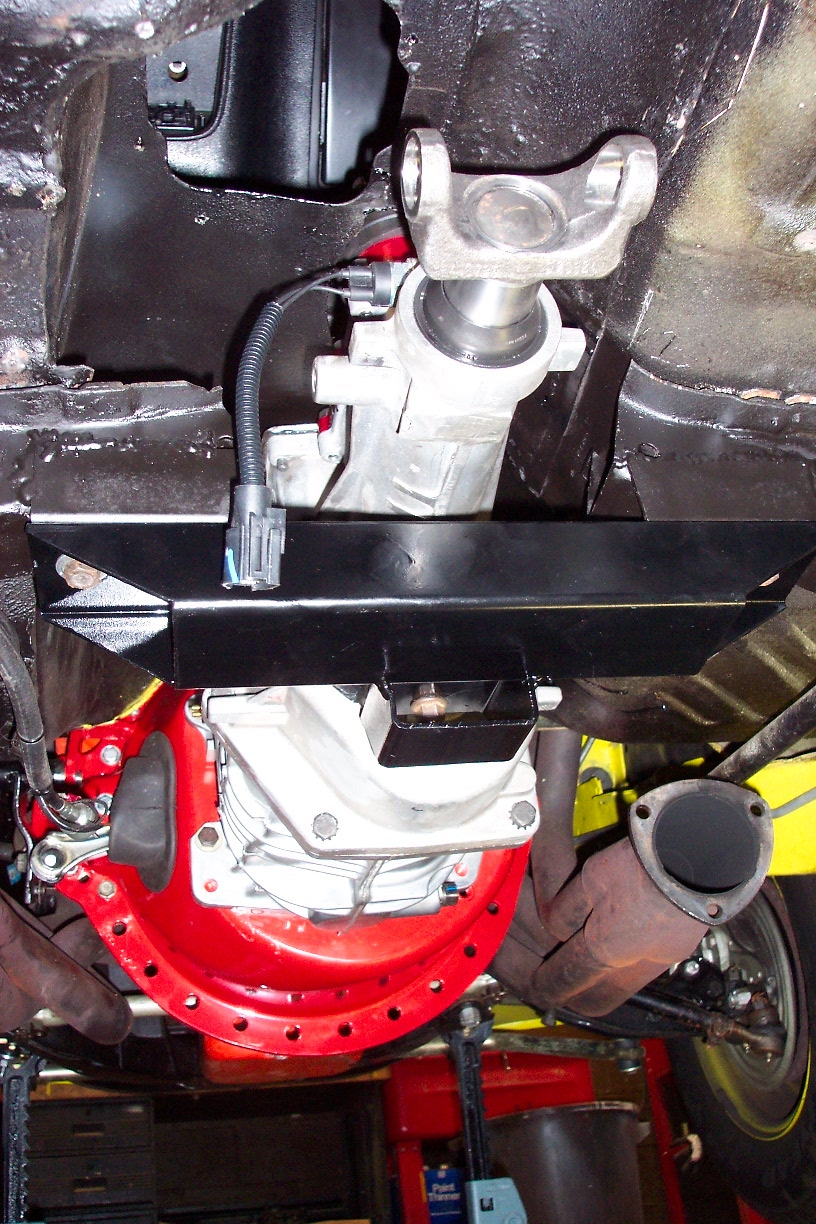

A worms eye view. Check out all that fab work using nothing but a Home Depot mig welder, sawzall and diegrinder with a cutoff wheel.

Stock Mopar shift fork and a modified (new bolt pattern drilled) lakewood scattershield.

Up top. The patch on the pass side of the hump was a bit overkill. I think that I could have got away with some more massaging with a big ole hammer.

I plan to make an shifter adapter to reposition the pistol grip closer to the stock location and with any luck I can hide it under the console.

Oh my lord!!

I made a quick adapter out of 2" x .250" to put the pistol grip back where I remembered it.

Drove the car today witht eh TKO 600 and the Dana and it ran flawlessly. Tranny is quiet and I love that 5th!! Cruising on the highway is so nice, with a 4.10 no less!!

Only gripe is since the shifter limit stops are inside the box, the lever doesn't hit as solid in each gear as it did with the ole Hurst Comp plus. No big thing though.

I'll probably try to hide the shifter adapter under a console I picked up.

I am very happy.

Tech Index