Moparts Tech Archive

Motor General

Cam tech, anyone?

Crazy73Moparts Member

Posts: 2884

From: Manchester CT

Registered: Dec 1999

Think that some things should be gone over, I'm on a knowledge search!

The following two are the most common terms you hear about camshafts, and are how I understand them. Am I right?

Lift

-basically, how far the camshaft tells the (rocker ratio) valve to open.

Duration

-how many (crankshaft) degrees the camshaft provides any lift.

Now for the hard-core tech stuff:

(help me out here)

Overlap

-This is how long the exhaust valve and intake valve are partially open at the same time.

--Other than bleeding off/maintaining cylinder pressures, what does this do?

Centerline

- I have a total blank on this one.

Lobe separation angle

- Is this the angle of the intake and exhaust valves?

-- What does a change in this do?

Lifter Velocity

- A greater lifter velocity allows more lift per given duration, which is why roller cams are so effective. The faster/easier a lifter can move across the cam lobe, the more lift you can cram under it?

Lets see whatcha got!

============================================

panic

Moparts Member

Posts: 1148

From: Long Island, New York

Registered: Nov 1999

posted 06-23-2002 05:59 PM

Lift: correct

Duration: close enough for a practical answer

Overlap: description is correct, but has NOTHING to do with cylinder pressure. Provides some additional cleansing of exhaust gas at higher speed, permits larger intake volume to enter.

Centerline: the 1/2-way point of the duration of each lobe (usually also the maximum lift point, but not always). Centerline can be moved with the timing keys, etc.

Lobe separation angle (also called lobe center angle) is the difference between the intake & exhaust centerlines. Close (in automotive installation, typically 102-108°) means good torque but poor low speed, power falls off a bit at max rpm. Wide (110-118°) has smoother low speed, lower cylinder pressure, power picks up at higher revs. Wide is frequently used in the following applications:

1. de-tunes a radical cam to make it more streetable

2. better for blower use

3. slightly reduces octane requirements

LSA is permanent - can't be changed (unless you have a dual cam motor). It's actually much more complex than this, don't try to figure out your own.

My article may help a bit:

http://victorylibrary.com/mopar/cam-tech.htm

============================================

DRAM

Moparts Member

Posts: 4196

From: West Palm Bch. Fl.

Registered: Jun 2000

posted 06-23-2002 07:41 PM

i don't quite agree on a couple of points written above. the overlap of a camshaft will indeed affect cylinder pressure, albeit a small amount. if you look at the explanation of how the LSA works you'll note that it does have an effect on how much overlap the cam has in it. you'll also note the differences in cylinder pressure and how the cam might behave...

these are things i've learned from practical experience, hope it helps...

============================================

Erson Cams: The Mystery Revealed

RobbMc

New Member

Posts: 61

From: Carson NV

Registered: Feb 2002

posted 11-03-2002 05:30 AM

Erson Cams is not dead, bankrupt, or out of business. I work there everyday as a design engineer and I still get paid every two weeks.

Mallory Ignition and Erson Cams were owned by Supershops. About four years ago, Supershops went bankrupt but not Mallory or Erson. They were sold to Dana and then to Mr. Gasket. The Mallory plant here in Carson City Nevada produces the Mallory, Erson, Accel and Hurst products. Almost everything is made in-house; all machined parts, molded parts and circuit boards.

The reason it is difficult to get Erson rockers from Summit is that Summit refuses to stock them. When you order them from Summit, they special order them from us.

Order direct by calling 775-882-6600 and ask for Steve Tanzi or Tom at extension 327. Tom races a big block Mopar with B1 heads and is very knowledgable. Steve is the cam master and knows more about valvetrain than anyone I know.

Erson is the only line we sell direct. Steve and Tom will give you a good price that will be close to Summit's price.

The Indy 440-1 heads require special rockers with a large offset on the intakes. Erson offers Mopar rockers for standard small and big block heads as well as Econo W2, W2, Indy 440-1, B1-BS, Stage IV/V and B1. Erson rockers have needle bearings and come completely assembled with 8620 shafts, spacers, and stands (if required). No modifications to the heads are required but you will need cup style pushrods. Prices vary depending on the heads but are around $550 to $650.

I designed all the Erson Mopar and Ford FE shaft mount rockers about five years ago. We have made continuous improvements and they are an excellent rocker especially for the price. I ran the first set of prototypes on my 340 Challenger. Those same rockers are still in use 5 years later on a circle track car. They have never been rebuilt.

Hope this answers some of the questions.

I'll try to check the forum from time to time to see if there are more questions.

============================================

Cam Tech

UDHarold

New Member

Posts: 45

From: Senatobia, MS, USA

Registered: Oct 2002

posted 01-18-2003 11:33 PM

--------------------------------------------------------------------------------

I believe Engle uses the 'One-Operator' method of grinding cams. That method has one person roughing and finishing each lobe in its' turn---All 8 exhausts first, then the LSA change, then all 8 intakes.

If the operator does everything right, then that cam is as accurate as any made.

HOWEVER, if the operator misses the LSA change, making it either too narrow or too wide, then the cam is ground with the wrong LSA.

Likewise if the operator selects the wrong masters, or puts them on reversed, or backwards.

These types of errors are common among companies using 'One-Operator' grinding techniques. Notice, if the cam is made right, then, it's right....

UltraDyne uses the 'Two-Operator' method, where the rougher has his own masters, and the finisher has his own masters. When the finisher finishes the cam, he must use the exact master numbers, and alignments, as the rougher. If their LSA settings are off by 0.5*(1/2 degree LSA error), the finisher catches it, as a large part of the cam is missed by the grinding wheel, and thus unground.

We do not ship mis-ground cams to customers.

We sometimes ship them the wrong cam, but at least it was ground correctly.

As far as I know, the only cam companies that use the 'two-operator' method are Crane, Comp Cams, and UltraDyne.

Crane started it, then Tom Woitesek left Crane and eventually organized the grinding dept at Comp Cams, where I was the cam designer. When I could not buy into Comp, I left and started UltraDyne, and hired people from Comp to grind for me, and of course, we used this method, as it is a 'self-inspection' method. The only time a cam can be ground wrong is when BOTH operators make the identical mistake, which is rare. Besides, at my place, we only aim for around 80 to 90 cams per week per pair of machines. Some companies want 200 cams per week......

As far as I know, no West-Coast companies use the 'two-operator' method.

UDHarold

====================================

Haney

Moparts Member

Posts: 551

From: Johnson City, TN

Registered: Dec 1999

posted 01-19-2003 10:07 AM

Great Info Harold!!! It sure is nice when "the man" from an aftermarket Perf. Parts supplier will take the time to check in and answer questions from the people who are actually using this stuff....

Very impressive

===================================

4x4 440

Moparts Member

Posts: 1409

From: Glenmoore,PA,US

Registered: Jun 2001

posted 01-19-2003 10:25 AM

I am glad to see guys like UDHarold and Scott from Straightline share their cam knowledge. Thanks guys and keep the information coming as the cam is the brains of the engine.

====================================

Is this cam OK to use? slight pitting (

GotBeep

Moparts Member

Posts: 523

From: Windsor, CA, USA

Registered: Jul 2002

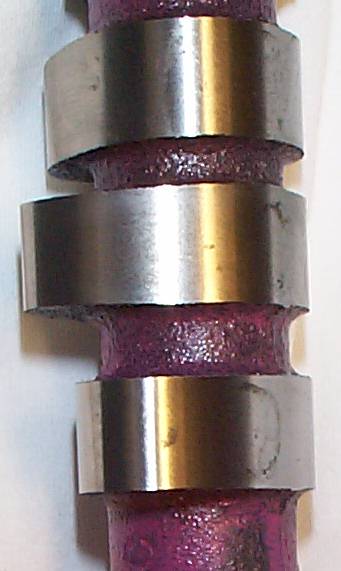

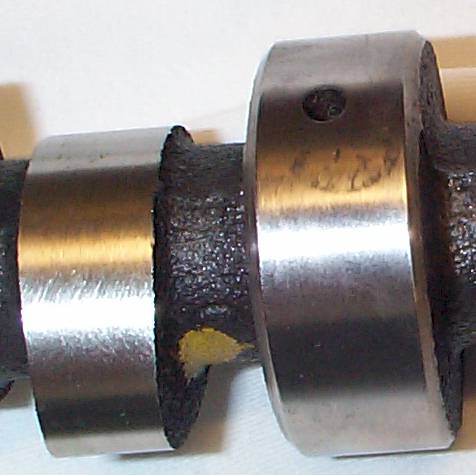

This is an MP 284/.484" I've had sitting in the orig box on my workbench for about a year. I looked at it a couple months ago and it seemed fine. We've had a lot of rain the past 6 weeks or so, and when I pulled it out last weekend to start tearing into the car and install it, I noticed the pitting.

These pics were taken after I had cleaned off the coating (cosmoline?) with laquer thinner. The pitting was not enough to catch your fingernail.

I used very fine-grade steel wool, the kind you use for wood-finishing, 000 I think. Some of the light pitting cleaned off with the wool, but some of the larger areas still have discoloration. I used compressed air to blow off any of the steel wool when I was done. Is the cam OK to use?

I have not looked at the lifters yet, but I expect them to be better because they're sealed in plastic. I have coated the cam in the assembly lube and wrapped it in plastic for now, to protect it since I cleaned off the last of the coating with laquer thinner.

It's not about the money -- I will buy a new cam if I have to. But I don't want to toss this one if I don't need to. I would appreciate both opinion and experience from the knowledgable amateur and professional engine builders on the board.

Also, what should I have done (what should I do in the future) to prevent this?

Thanks

====================================

DLank68

Moparts Member

Posts: 430

From: Alton. Illinois

Registered: Nov 2002

posted 01-19-2003 09:17 PM

i used a new one like that, actully i think it was worse.. but it had pited, but it was sealed power cam OEM 340 cam.. i went ahead and used it in a 318, its worked good...... no problems drove it every day for 2 years 50 miles a day, then i tore the engine down, the cam looked good as the day i put it in

====================================

DRAM

Moparts Member

Posts: 5088

From: West Palm Bch. Fl.

Registered: Jun 2000

posted 01-20-2003 11:22 AM

from what i see in the pics, i wouldn't be afraid to use it.

======================================

Tech Index