Moparts Tech Archive

Small Block

Stroker Dis-assembly

416" Tear Down.... MANY Pics69DartGT360

Moparts Member

Posts: 3233

From: State College PA.

Registered: Apr 2000

Well Pulled the 416 last night in the rain with the help of "dkj103" Finally got around to tearing it down this afternoon. For those who don't know, I sold the W-2 heads, that would be the reason for engine removal. Also I'm stepping up to a solid Roller and will need to bush the lifter bores, so motor had to come apart. I was also curious just to see what kind of shape it was in. So While I was disassembling I figured I'd snap a few pics and maybe those guys who are currently building or thinking about building a 4" stroker motor would like to see what goes into one.......Keep in mind this engine has 14 dragstrip passes, with slowest one being 11.20 @ 119 MPH and quickest being 10.75 @ 125.24 MPH and put out 450 RWHP and 516 ft. lbs on the Chassis Dyno on Friday afternoon. (4 dyno pulls) also has about 200 street miles on it.

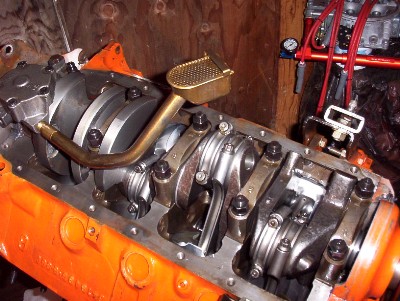

Yanked the heads and here is what we have...

No this pic was not taken during the engine build! LOL This was taken this afternoon during disassembly..... Not much carbon on those pistons eh? ARP W-2 Head studs.....

These are Ross Forged pistons. They are domed to work with the open Chamber W-2's.... This motor is a 4.07" bore '72 360 that uses .030" 340 " stroker pistons.

Piston #2 at TDC .005" in the hole.

One more pic of the slugs..... +6cc dome. Actual compression was 12.23:1 with a Fel Pro 1008 Gasket and open Chamber W-2's.

Milodon 7 Qt pan off........ M7HV Oil pump clears both the pan and the counterweights on the 4" crank with no grinding required.

SCAT H beams and ARP Main studs...... The SCAT's use an ARP 4340 7/16" cap Screw..... The MP 4" crank is also manufactured by SCAT.....

69DartGT360

Moparts Member

Posts: 3233

From: State College PA.

Registered: Apr 2000

Alot of Questions come up regarding balancing....... So here are a couple pics of the balance work. I had mine INTERNALLY balanced. Which means I used a neutral balance flexplate and SFI internal balance damper and had Mallroy metal added to the crankshaft.... Mine required 3.5 slugs..... here are the rear 2

The machine shop has to grind notches in the rear crank flange to allow their drill to reach the back of the counterweight. because this is a CAST crank, the slugs have to be installed this way. The slugs are then welded in. Keep in mind each slug is ~$50. EXPENSIVE metal! LOL

These slugs are in the forward most counterweight, and they had some material removed from each, giving me the 3.5 total..... (but unfortunately I had to pay for 4 slugs to get 3.5..) Keep in mind the lighter the bobweight the less slugs required.

Strokers require special pistons due to their obvious added stroke. Here is a pin location shot on a 4" slug..... If you tried to run a std. 340/360 piston in a stroker application the piston would stick WAY up out of the deck.......

Shot of the SCAT H beam. You can see why they are soo much stronger than stock! LOL Also that is one of the cap screws on the right....... And if you notice how the bottom of the piston sort of has a semi-circle shape to it? That is intentional, the huge crank counterweights on the 4" crank BARELY clear the bottom of the piston!

Rod bearings for a 4" crank MUST have a full radius (hard to see in this pic but....) Clevite Part # CB481H keep in mind they are nearly 4 times as expensive as regular CB481P clevite Rod Bearings... But you don't have a choice! Thanksfully Mine all came out looking like new.

Luckily I did'nt find any surpirises, the bearings all looked like new, I DID have some slight cap walk, but I was talking with "mrw5" the other week and he said there is bascially no way to avoid it on SB Mopars. In high HP applications you will have SOME walk. I have a short fill of Hard Block, fresh line hone, and use ARP main studs.... Not much more I can do with a stock block short of Pro Gram 4 bolt caps..... (not in my budget) I tried to get a pic of the "walk" but it did'nt come out right...... But it was'nt significant, did'nt bother me. Cam looked great, heads look great etc etc. All ready for re-assembly! .700" Solid Roller and a set of Either Max ported W-2's or a set of W-5's should put the car in the high 9's next year.

Tech Index