Moparts Tech Archive

Front Suspension

Control Arm Bushings

Off-set upper control arm bushings?ff6849

Moparts Member

Posts: 150

From: Yuma, Az, USA

Registered: Mar 2002

posted 11-17-2002 01:18 AM

Has anyone used the offset bushings in their upper control arms, and if so which way dose the offset go. I just completely remove the front suspension from my car; replacing all the bushings, and ball joints including torsion bars, and upgrading tie rods, have to start putting it back together. This is the first time I have attempted a project this big unable to find anything in the tech section, as to what direction-offset bushings are pressed in. Trying to find a shop around town to press them, but what to make sure I know which way is right to be sure. I get different answers from different shops, starting to worry no one seems to know how to work on mopars around here. I am thinking of returning them for regular bushings. The LCA sounds like real fun from what I read in the tech section

==========================================

carl

Moparts

Posts: 8648

From: Ohio

Registered: Nov 1999

From auto-x's site.

heres the link;

http://hometown.aol.com/pwall5/cars/tips.html

the link is also in the tech area in the special parts thread.

I need to move it into the front susp thread also.

carl

===========================================

autoxcuda

Moparts Member

Posts: 1032

From:

Registered: Jan 2000

This pic is also from my website:

These are pics from a Richard Eherenberg MA article.

I think I read in the last mopar action about someone that has nice tools to take out the upper and lower bushings. You'd have to do a price comparsion to what the shops are going to charge you and how many times you think you'll do this in the future.

Steve Wall

So Cal

=========================================

Found a new way to get those darn LCA bushing shells out.

goldduster318

Moparts Member

Posts: 2009

From: Corry, Pennsylvania

Registered: Mar 2000

Well guys after putting this off for a long time because I knew that it would be a very hard thing to do, I figured out an easier way to get those darn Lower Control Arm bushing shells off. I basically cut into the shell about 1/3 of the way, all the way around to the lip and then folded the shell inward enough so that it would hold and still allow a 1/2" threaded rod to run through it. I then slipped a washer behind the folded shell and shoved the threaded rod through and installed a nut on the back. Using a pipe fitting, I tightened the nut until the shell extracted itself out...Was a total breeze.

Here are some pics:

What do you guys think...It seemed pretty easy to me. I had two of them out in 1/2 an hour!

LCA bushing sleeve removal tip....pics

340_6Pak_Cuda

Moparts Member

Posts: 2527

From: Maryland

Registered: Nov 2001

I just thought I would share this with everyone because it worked so well. Most people say to chisel the bushing shell out of the lca but that sounded like work to me so I came up with an easier way.

Here is a pic with the pin pressed out and the rubber removed. Once the pin was out I plucked the rubber out with a screwdriver.

Next I welded a washer to the outside lip of the bushing shell.

The washer gives you something to press against. I put it in the press and it came right out. Total time for 2 lower contol arms, 30 minutes.

---------------------------------

kekoakeakane

Moparts Member

Posts: 996

From: Honolulu, HI USA

Registered: Jun 2001

posted 09-26-2002 04:32 PM

--------------------------------------------------------------------------------

The other approach I've heard of is to use a 1 1/4" tap and thread that into the shell. It will cut into the shell, but not the LCA. Then just press the tap out. If you know a plumber, they should have these in NPT thread.

Kekoakeakane

----------------------------------

Sixpak

Moparts Member

Posts: 2340

From:

Registered: Jan 2000

posted 09-26-2002 05:50 PM

--------------------------------------------------------------------------------

I've also taken a sawzall and split one side of the sleeve, so that with a couple of shots with the chisel the sleeve can be folded inward on itself, losing its grip. But that washer trick looks neat, too.

-----------------------------------------

Are lower control arms the same on a 71 B-body w/disk and a 71 w/drums.

Prochargedmopar

Moparts Member

Posts: 894

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 05-27-2002 04:01 AM

My drivers lower control are is worn out and the bushing will not fit snugly. Can these be swapped in??

=============================================

4speeds4me

Moparts Member

Posts: 2339

From: Sicamous, B.C., CANADA

Registered: Sep 2001

posted 05-27-2002 04:06 AM

Yes. For the money, and if you have any, I'd rebush the entire frontend. I got a poly kit for my Duster from Energy for about $200CDN. Well worth it, IMHO.

Worse case scenario, if you don't have the scratch. then that's the patch. Use the other lowers.

=============================================

Prochargedmopar

Moparts Member

Posts: 894

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 05-27-2002 04:00 PM

Thanks!

I rebuilt the entire front end With Performance Suspension poly kit. When I reused the old outer bushing I noticed it had a little "slack" in the lower arm. I went ahead and completed the rebuild but it aint "right". Should have swaped them when I had it apart. Maybe I can use the one in the backup arm with out buying any parts at all. Thanks again 4S4M.

=============================================

Fred Goodwin

Moparts Member

Posts: 218

From: Sunset Beach, H.I. USA

Registered: Nov 1999

posted 05-27-2002 04:15 PM

Yes, the control arms are the same, only the spindles are different. They should interchange okay. Fred.

============================================

4speeds4me

Moparts Member

Posts: 2339

From: Sicamous, B.C., CANADA

Registered: Sep 2001

posted 05-29-2002 03:47 AM

There are some that say not to use the poly bushings in the lower anyways, so I guess it's your call. Did you take the outer shell out of the LCA? Just curious, as I left mine in, and I have no issues with fit.

=============================================

Prochargedmopar

Moparts Member

Posts: 894

From: W. of FTW...Granbury, Tx

Registered: Sep 2001

posted 05-29-2002 08:38 AM

Yes I left mine in. It was not a press fit in the one lower on the pass. side. I feel that a new bushing might have been tight as the old one had been slippin around and might have even worn the control arm making a new one loose too. I'll see next month if I can get to it. To many other projects going on now.

============================================

info provided by members listed above

Lower Control Arm question-again-

dtdickens

posted 12-27-2001 07:02 PM

Got another set of LCA's...I did as you guys suggested, I took the torch and heated the rubber up and the bolt and inner bushing just fell out-GREAT! Now....can you tell me any tips on getting the outter shell off of the arms...and the inner shell off of the LCA bolt.

Is grinding & chisel the only way??

Also....is it ok for the hex/adjuster assembly(inside the arm itself) to be loose? How much is too loose, as far a sideplay, to be considered worn out? They are not sloppy, just have a little movement side to side.

I know you guys get tired of LCA questions.

==========================================

GregZ

posted 12-27-2001 07:23 PM

I slit the inner sleeve with a cut off wheel (in a die grinder)then air chisel it off, and just use the air chisel on the outter sleeve. The outter one takes a bit of time.

=========================================

ragtopdodge

posted 12-27-2001 08:02 PM

Does one need to take out the outer shell (left in the LCA) if you're using Urethane/Polygraphite bushings?

========================================

GregZ

posted 12-27-2001 08:08 PM

the outter sleeve can stay if you are using poly bushings. Personally, i refuse to install poly LCA bushings on mopars with torsion bars. The rubber bushings actually help retain the arm onto the pin, and poly bushing do not do this. This can allow LCA movement in some cars, which can cause clunks (not always) and alignment changes as the arm slides fore and aft on the pin. I checked the pressure needed to properly install the pivot pin into a rubber bushing on my press. Peak pressure was over 2 tons. The pin slid in by hand with poly bushing.

=======================================

dtdickens

posted 12-27-2001 10:58 PM

Thanks Gregz (and others)...I remember some time ago when that topic came up (lower poly's), and after actually seeing how the bolt is pressed into the inner sleeve and vulcanized rubber keeping it put with the outter shell...I see how much better a system it is -vs- just sticking the Poly Gromment in there. Should be a much stronger joint. With the polys, I saw what you guys were talking about...there is nothing that really holds the bolt in place...other than the back of the TB and the side load of the strut. Going Poly everwhere else. I don't like the idea of a single spring clip, keeping that joker in place so to speak.

From what I can tell/heard Ragtop, you leave the outer shell in for the polys. After actually taking it apart...I prefer the rubber system, but to each his own.

Thanks guys for any and all tips!

==========================================

carl

Moparts

=========================================

ggordon

posted 12-28-2001 12:40 AM

Dad burn you guys. I've been putting polygraphite LCA bushings in my cars, and now you've got me worring. (I sidelight as a professional fretter:"My front end is gonna come apart, My front end is gonna come apart.")

Naaaaaaaaaaaaaaaa. The LCA is triangulated with the brake reaction strut. It is captured. No way. IF that (comming out) was the case, think of all the cars with bad OE rubber bushings that would have crashed back in the day they were plentyful. And there were plenty running around with bad ones.

Hopefully with the stiff poly strut bushing (which I use)it is not going to change toe. But you're right, is does make you wonder if it is moving back and forth. So far my alignments are holding great.

By the way, when I first started fiddling with these cars, the only way I could find OEM style rubber doughnut strut bushing at the auto parts store for 73 and up A bodies, was to ask for some for an E body. Don't ya love their computers and counter help?

===========================================

Some Car Guy

posted 12-28-2001 02:24 AM

Umm, it's been awhile so this may be way off base......

Doesn't the t-bar tensioner hold the bar in a "bind" so to speak? I would think that that would prohibit this "fore and aft" play we are discussing. I refuse to believe that that stupid little clip at the back is all that is holding the t-bar and front end together in my car

==========================================

Satilite73

posted 12-28-2001 02:39 AM

Oy! Here we go again! The last time this was discussed, it was determined there are two kinds of poly LCA bushings. One is the bare poly that reuses your old shells and a poly bushing that comes with with shells attached already.

I had the first style in my wagon. Got all kinds of clunking/banging sounds from the front and the car handled TERRIBLE, felt like it had bias plys on the front. There WAS fore/aft movement of the LCA on the bushing. Not ALOT, but isn't any fore/aft movement bad? Swapped in stock rubber LCA bushings (didn't even realign or anything) and the car handles GREAT now! A total day/night kinda difference and no more noises.

John

========================================

ggordon

posted 12-28-2001 09:31 AM

It seems to me that the way Chrysler designed it, they have allready thought of this. (surprise, surprise).

Ok, I am figuring that the spindle's thrust is almost always aft. It is causing the LCA to "pivot" at the brake reaction strut attach point. This pushes the bushing end foward, making it even better.(more secure)

In other words it forcing the thing to be more "assembled" while you are riding down the road.(That's why you have the big trurst area on the poly bushing) The only time the spindle is pushed forward is when you are backing up.

The only "problem" I have seen is the OE rubber wears out. Then the LCA flops in the caster axis causing the strut rod to beat hole in the K frame and it wallers out.

===========================================

ggordon

posted 12-28-2001 09:38 AM

That's why those stiff polygraf. bushings on the brake strut are nice. Keeps caster. Or is it toe?

===========================================

TheOtherDodge

posted 12-28-2001 10:06 AM

Lovely..I wish this thread came up a week ago. I am replacing my worn LCA bushing and strut rod bushings with poly ones. I have not got the new ones in yet (hopefully today).

So is using the poly ones for the LCA a bad deal???? Let me know before I do it!!!!

========================================

dtdickens

posted 12-28-2001 10:36 AM

No...didn't want to start the "War of the Polys"--I saw it fought a little- long ago, and it wasn't pretty ...I see how the LCA bolt is triangulated-via the strut rod-but for some strange reasons...during Braking/ Hard Accel(which the strut rod is supposed to be one of the limiting factors) tends to allow "Some" to hear the movement of the arm against the back side of the TB, others have pryed against the arm on a lift, and seen the movement in that area, ie back and forth motion on the arm itself-- while others have NO ISSUES at all. Maybe just a stackup of production tolerances being the factor on different vehicles. Knowing that Murphy usually stays in my back pocket...figured I didn't want to take that chance. I hate tearing stuff apart twice, and hate creeks, bumps, moans(well, some moans are good ) and rattles. Unfortunately when I ordered my PST kit, I got the plain bushing, more like a grommet really. By comparison, the OE is a better/stronger joint "in itself". If they make a shell in a shell poly bushings, that might be the cat's meow, I've never seen one...but might order 2 to check them out..anyone got a source? Greg already stated that the bolt on the "grommet style" poly is pushed in via hand...while it takes 2 tons or more of force to seat the bolt/outer shell/OE bushing in it's desired location. That's enough proof for me on the stronger joint theory + any triangle or side load- is only as strong as it's weakest corner-the reason for the "bump" on those vehicles which allow such a thing. There was also some Suspension Guru, who I understand wrote a book, can't but remember his name...that recommends NOT using poly in the LCA's, but recommends it everywhere else. Sure someone here has the book, seen it quoted before.

I admit the clip isn't the safety workhorse on the T bars...wind-up/tension is, as far as keeping them in place-my "Fupar".

Hey, I was just looking for tips for tearing this stuff apart & putting it back together. It seems that whenever anyone mentions the LCA's on a Mopar....it's like India and Pakistan rattling their sabers at one another over a border conflict ....God, I love this place, really! Wife has to threaten to jack-slap me off the puter sometimes. It's all in good learning/fun so to speak--LOve U all just the same!

Thanks guys for all your help!

==========================================

dtdickens

posted 12-28-2001 10:41 AM

Big Thanks!!! "to Carl"- for the Suspension Stuff in the Tech archive! Great stuff!....If I only had broadband!! Well...will get a cup of coffee while it loads.

==========================================

TheOtherDodge

posted 12-28-2001 11:18 AM

I just talked to PST, since I ordered my poly LCA bushings from them, and they said there is no problem with using them and could not give me any explanation (becuase he said he was not aware of a problem). He feels comfortable that there is no problem with using them.

Should I just use the stock rubber ones instead? I want to know now, so I don't have to tear everything back down again...

=========================================

roadrunner7070

posted 12-28-2001 11:18 AM

This past summer I replaced everything up front with the poly bushings except the LCA bushings. I heard so many people debating this that I decided to do the LCA bushings in rubber. Bought them from PST but have not installed yet. The nice thing about the rubber is that they are 1 piece complete with the inner and outer sleeves and were only $10 each. No burning out of the old ones. Just press new shell in after removing old shell.

===========================================

Satilite73

posted 12-28-2001 11:38 AM

TOD, based on my experiences with poly lower bushings, I'd go with rubber in the LCA and poly at the strut rod. My car handled TERRIBLE with the poly LCA bushings, darted around, grabbed grooves, etc. etc.. If had this much problem at speeds 70 and below, I REALLY wouldn't want to find out how bad it is at over 100!!

John

==========================================

dtdickens

posted 12-28-2001 12:10 PM

Carparts.com has Moogs for around 11 bucks each-part #k791.

My local Carquest had the same part # and got them around the same price, within 24 hrs. They say "made by Moog" as well.

I'd go with rubber(OE) and poly everywhere else. If you can find the shell-in-shell poly's...that might be an option. Where do you get them? I'd like to look at one/two.

===========================================

Dennis

posted 12-28-2001 12:54 PM

If someone is making polygraphite LCA bushings with shells, I'd love to know who it is, since all of mine are of the insert type. I haven't had a lot of problems with them, but I would rather have the entire shell and all to install just for my own peace of mind. Dennis

===========================================

Satilite73

posted 12-28-2001 01:15 PM

Hmmm.......coulda sworn last time someone said they had lower poly bushings with shells. Too bad the topic didn't get archived.

If it makes a difference, I bought my kit from PSC in Phoenix, AZ.

John

===========================================

DGLogan

posted 12-28-2001 01:52 PM

I'm finally finishing up a complete front end rebuild on my '69 Dart and I'm using poly LCA non-shell bushings (and poly everywhere else, too). They have gone together just fine and I currently see no way that they are going to cause any problems. The pin fits tight into the LCA poly bushing (used the special grease and inserted it by hand). My old parts were also in great shape (which may be causing some of the complaints with poly LCAs), as I inspected, cleaned, bead-blasted and painted each part prior to assembly. Converting to '73-up slider disc brakes, too. My poly front end parts came from ESPO in PA.

Once I get the car up and running, I'll be happy to provide an update (good or bad) as to how the car handles.

==========================================

GregZ

posted 12-28-2001 02:27 PM

"The pin fits tight into the LCA poly bushing (used the special grease and inserted it by hand)"

This is the cause of the problems with the poly bushings.as I said earlier "I checked the pressure needed to properly install the pivot pin into a rubber bushing on my press. Peak pressure was over 2 tons."

You may not notice any clunking while driving, but after you install everything, jack the car up, and using a big pry bar between the LCA and the k-frame, just to the outside of the pivot point, give a good pry. You'll see the arm slid back a little off the pin.

===========================================

Control arm bushings -- press out?

Jim RabidWolf

posted 03-19-2002 11:42 PM

Anyone had decent luck pressing out upper control arm bushings themselves? I need to blast and paint these pups and I don't relish running back and forth to a machine shop to have them pressed out and in.

I have a HUGE 'c' clamp with lost of beef and thought about use appropriate sized sockets or pipe to push these out and in. Never done it on a truck. (externals were easy -- popped them out with a pickle fork)

How tight are these little monsters????

==========================================

kekoakeakane

posted 03-20-2002 12:41 AM

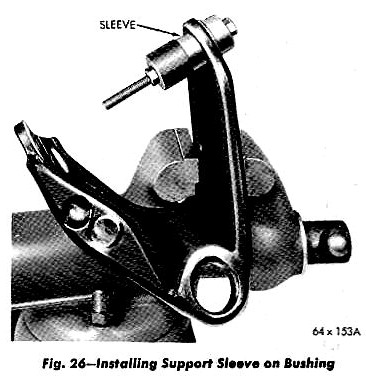

I've had good luck on a hydraulic press. You could always attempt the method used in the book with their special tool that actually looks like a socket and threaded rod. (See Below)

Kekoakeakane

MOPAR No Ka Oi

===========================================

340wonder

posted 03-20-2002 12:52 AM

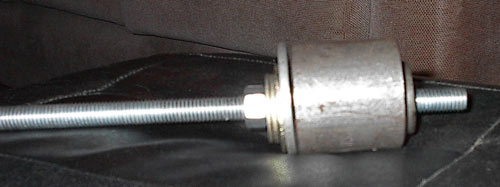

I pressed mine out with a home made jack screw. You need threaded bar stock 1/2' me thinks, piece of pipe, two nuts, and some big washers. Weld a nut to one end of the bar, place a washer on the rod, put the pipe over the bushing from the outside and slide the rod through the bushing, install another washer and nut. hold one nut with a wrench and use an impact on the other (impact not needed but much easier). When you tighten the nut down it will drive out the bushing. I used the same to install the new bushings.

===========================================

Tech Index