Moparts Tech Archive

Front Suspension

Torsion Bars Install Questions

69 GTS 4-spdMoparts Member

Posts: 264

From: Big Lake MN USA

Registered: Oct 2001

I just learned that there is such a thing as left and right torsion bars on my 69 GTS,I took them both out when I replaced the frame and now I don't know if I mixed them up or not!!!! Mine have part numbers on the end of them but I see nothing refering to left or right(please Help)

Dave

--------------------------------------------

carl

Moderator

Posts: 7094

From: Ohio

Registered: Nov 1999

When there is a 'pair' of parts like in this case the odd # always goes on the left or drivers side of the car and the even #'s goes to the pass side.

carl

---------------------------------------------

451boy

Moparts Member

Posts: 4536

From: Oregon

Registered: Nov 1999

As Carl says but also, the torsion bars are marked L and R. There is a third ID on the bars which is the paint splotches. 2 splotches on the left, 1 on the right. That makes 3 different ways the factory marked these bars left and right. Guess they were serious about it!

Come to think of it, there is a 4th way to tell L from R torsion bars. This method works even if the numbers are ground off and the paint splotches are gone. The bars are pre-set twisted 30 degrees in the direction of use. So you can look down the bar and see which way the bar is twisted. Bars twisted clockwise (looking from the rear) go on the right side, bars twisted counter-clockwise go on the drivers side.

---------------------------------------------

all info provided be board members listed above.

Grease seals for torsion bars

Steve Baer

Moparts Member

Posts: 120

From: Champaign, IL USA

Registered: Nov 1999

posted 04-10-2002 01:09 PM

I'm helping a friend who is rebuilding the front end on a '70 Coronet R/T. He has replaced all the bushings (polygraphite except for the lca bushings, which he replaced with rubber), ball joints and inner and outer tie rods. He is reusing the stock original torsion bars. The problem he's having is with the rubber “seal” that the torsion bar passes through where the torsion bar anchors in the crossmember; the openings for the torsion bars in the replacement seals seem WAY too small for the torsion bar to pass through. He says if he tries to shove the torsion bar through the seal it will rip the hell out of it. He says it looks like it's the wrong seal. Would the seal possibly be for 6-cyl. torsion bars? (I couldn't find anything about this in the tech forum.) He says the shop manual advises packing the seal full of grease prior to installation. What the heck is up with these seals? He didn't want to order replacement seals unless the ones he has are for sure wrong for this application. Any help you guys could provide would sure be appreciated. Thanks!

===========================================

ZIPPY

Moparts Member

Posts: 4364

From: Detroit suburbs MI USA

Registered: Jan 2000

posted 04-10-2002 01:14 PM

Lube the seal, slide it over the torsion bar, *then* put the end of the torsion bar in the socket and push the seal over the socket.

If he tries to leave them on the socket and shove the bar through, yes he will tear them up.

============================================

Duster62360

Moparts Member

Posts: 658

From: Leucadia, CA, USA

Registered: Feb 2001

posted 04-10-2002 01:24 PM

If he's got the thick rubber (poly??) ones that came with the kit, I can feel his pain. I greased the hell out of mine & still couldn't get 'em on. I gave up & bought a set of regular ones from the dealer.

============================================

classj

Moparts Member

Posts: 121

From:

Registered: Apr 2002

posted 04-10-2002 03:55 PM

The poly ones I used were a pain. But with a dose of silicone grease and two people. One holding the bar against the ground and another pressing the seal down with a block of wood, I got them on. And that was easy compared to getting them over the crossmember. It took a while to figure out how to do it but I finally got them in. To top it off I am using the 1.14" bars. If they come out again I am going to definatly use rubber. Some of even the best poly fits poorly.

============================================

MTTwister

Moparts Member

Posts: 217

From: Butte, MT USA

Registered: Sep 2001

posted 04-10-2002 06:37 PM

It was on a 72 duster - and rubber boots, but I cut the pouring end off a plastic bottle of "Heat" ( a round bottle, not an asymetrical shape) so that is was a funnel-like conical adapter. The cut end was large enough to fit over the end of the torsion bar. The pouring end was about 1/2 ". Used that to help stretch the 'boot' over the end of the torsion bar.

Your's could be a totally different set up, but using somethikng shaped like a funnel could help.

============================================

all info provided be board members listed above

Is there a front and rear to these? Does it matter?

Red383

Moparts Member

Posts: 360

From: Fort Loramie, Ohio

Registered: Nov 1999

posted 04-10-2002 08:13 AM

Is there a front and rear to these? Does it matter?

Thanks.

============================================

GregZ

Moparts Member

Posts: 3638

From: Southold,NY

Registered: Nov 1999

posted 04-10-2002 08:38 AM

There is a left and a right. They are marked on the end with an "L' and an "R". on the same end , there is usually a 3 digit # which is the last three of the part #. Typically, the odd # is left, and even is right. There are some heavy duty and race applications that are exceptions. There is no front or back, but most bars are installed so you can see the 3 digit # and the "L" or "R" through the cross member hex hole.

===========================================

all info provided by members listed above

Torsion Bar Tool?

cudarex

Moparts Member

Posts: 275

From: odessa, tx

Registered: Dec 2001

posted 05-20-2002 01:11 PM

Does anybody have the website for the torsion bar removal tool? I think Miller tool makes it but not sure.

===========================================

Bad340fish

Moparts Member

Posts: 125

From: Tulsa, OK

Registered: Apr 2002

posted 05-20-2002 01:15 PM

I have been lucky I guess. I can just get a set of vice grips on the torsion bar and whack it with a hammer and it comes right out. But my torsion bars have been in and out many times in the last few years so that may have something to do with it. Might be worth a shot before dropping the cash on a tool.

Clark

===========================================

69Satellite

Moparts Member

Posts: 749

From: Los Angeles, CA

Registered: Apr 2001

posted 05-20-2002 01:20 PM

The only problem with putting vice grips on them is that the possibility of nicking or damaging the bars is higher with that method. Not a big deal if you're taking old ones out, but a bigger deal if you're putting new ones in.

Chris

============================================

451boy

Moparts Member

Posts: 4495

From: Oregon

Registered: Nov 1999

posted 05-20-2002 01:25 PM

Yep, Miller Special tools still has that tool available. There is a guy selling a tool very similiar to the Miller tool. I saw his ad in one of the Mopar magazines the other day. Either tool was around $80 or so.

Vise grips is a no no. That is like using vise grips to compress valve springs. Torsion bars are very highly stressed suspension members and should not be nicked or damaged.

============================================

sloduster

New Member

Posts: 30

From: las vegas,nevada usa

Registered: Mar 2002

posted 05-20-2002 01:50 PM

I use the clamps that come with those spring lox kits from the auto parts stor than I clamp a vise grip over a rag right next to it and smack the grip against the clamp

==========================================

cudarex

Moparts Member

Posts: 275

From: odessa, tx

Registered: Dec 2001

posted 05-20-2002 02:29 PM

Thanks for the replys. I'm really in a mess.

When I installed the bar as I was whacking it from the rear to get to go into the LCA I noticed it didn't want to go in as easy as the other side did so I just whacked it harder and now it is half way into the LCA socket and I can't budge it either way now. It is really wedged in there now. Guess I didn't clean enough of the powder coating out of the socket. Right now I have the LCA just hangin loose with the torsion bar attached. I tried whacking on the LCA socket lip with a pipe wrench and hammer with no luck yet. I gess tonight I'll try a bigger hammer. If I ever get it off I'll be sure and clean the socket and lube well.

===========================================

kekoakeakane

Moparts Member

Posts: 911

From: Honolulu, HI USA

Registered: Jun 2001

posted 05-20-2002 02:38 PM

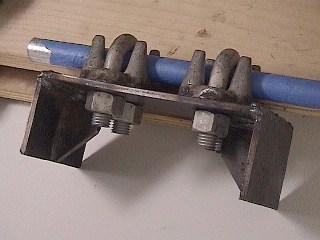

I've used 2 DIY type T-bar tools with success. My first version includes a 1/4" thick 8" corner brace and 1" U-bolts from a hardware store. About $10 in parts. It should be hit from the inside of the brace where I'm pointing.

Version 2 uses 1/4" flat steel I got as scrap from a steel shop and 1" cable clamps. It's a much sturdier version. Cost is about $20 in parts, but you need access to a welder.

BTW, I've been noticing how large the factory tool is and it probably works fine with the stock exhaust, but I can see definite problems if you have headers installed.

============================================

Leigh

Moparts Member

Posts: 1544

From: Censored, MN

Registered: Mar 2000

posted 05-20-2002 06:27 PM

Take a pry bar and pry down on the lever that is attached to the control arm t/bar socket. It can move another 1/2" or so, allowing the socket to align with the bar, which is usually enough to let it drop right in. Good luck.

============================================

MagnumDart

Moparts Member

Posts: 131

From: Illinois

Registered: Apr 2001

posted 05-20-2002 06:53 PM

If you break the lower control arm free it may slide in easier. Just 2 or 3 free threads or play may help align it.

============================================

hemigtx

Moparts Member

Posts: 151

From: sacramento, CA usa

Registered: Jun 2001

posted 05-20-2002 08:59 PM

Miller tool# C-3728 $71.35 and still available. 1-800-801-5420. Hope that helps.

==========================================

all info provided be members listed above

The pic below shows the orientation of the rear anchor in the frame for the TB

Aussie

New Member

Posts: 4

From: Australia

Registered: Nov 2002

posted 11-15-2002 08:04 AM

Could anyone give me some help in this area.

I have a 318 Barracuda that rides really high and really soft in the front end...even after adding heavy duty shocks. By winding the torsion bars down to lower the vehicle will this give the car a firmer ride or will it just make the car sit lower ??? I also have a set of Hemi torsion bars at my disposal....by fitting these bars will i be able to lower the vehicle or will it just give it a firm ride at the expence of a higher ride height because i am lacking the weight of the Hemi motor to keep the vehicle down low... I have not had any experiance with torsion bars before and wanted some help by those that have done it before. I was afraid that by using the Hemi torsion bars the front end would be too stiff and would not be able to be lowered. Any kind of help would be greatly appreciated.

Thank you evryone for your time and help.

A wonderful site.

==========================================

jamesc

Moparts Member

Posts: 3933

From: Peoples Republic of New Jersey

Registered: May 2001

posted 11-15-2002 08:18 AM

welcome aboard

actually i would "think" the preload is dependant on the weight of the car. adjusting the bars should really only effect the ride height. i don't believe adjusting the bars should have much/any effect on the ride quality.

i'd give the heavier bars a shot.

remember there's a left and a right. also they are a spring so NO nicking or beating them up.

Oh yea.....as long as it's soft, it won't handle well. Just the way it is. Stiffen the ride, handling improves. A sway really helps too!

=========================================

dbdartman

Moparts

Posts: 3934

From: Trenton, NJ

Registered: Nov 1999

posted 11-15-2002 02:00 PM

--------------------------------------------------------------------------------

James is right, the spring rate (once the front end is off the stops) doesn't change, only the ride hight. Torsion bars ARE springs, & as such, subject to wear. Sounds like your current bars are pretty worn, or are too small. Personally I prefer a firm ride (some call it STIFF!) & use even larger than the Hemi bars in my Dart.

Look for a partial part # on the end or the Hemi bars, odd on left, even on right (I think). They MUST\ be installed on the proper side (if they are already used). There is no "front" or "back" (dont worry about which end goes F or B) but there IS side to side.

New bars are available here, about $120 US, & available in a variety of sizes (from about 0.8inch to 1.125 inch). Mine are, I believe, 1.0 inch.

DB

=========================================

HEMIRR68

Moparts Member

Posts: 254

From: North salem,NY USA

Registered: Apr 2001

posted 11-15-2002 07:42 PM

Just put in a new set of .960 mopar performance bars one size thicker than stock restoration size better for handling,you nmust first remove upper rubber bumper, then lift car off ground from k member pull out rear spring clips, dont use vise grips, there is a special tool to bang out bars, but first loosen adjusting bolt, then bang out. remember left and right side, remember left side is drivers side when putting in new ones

=======================================

Frenchy72

New Member

Posts: 62

From: Wilmington NC USA

Registered: Jul 2002

posted 11-15-2002 07:55 PM

1 inch bars give a very nice ride in a small block E-body.Even with KYB's and low profile tires. Don't forget a suitable sway bar too.

=========================================

dtdickens

Moparts Member

Posts: 2560

From: Littleton,NC , USA

Registered: Dec 1999

posted 11-15-2002 08:45 PM

I've got the BB 383 bars in my 340 clone Swinger. I have it "rough adjusted", since I don't have all the body parts on it yet.

Upon windup....I basically backed the T bar screw all the way down then went back up until the adjuster bolt hit the adjuster and "just" started adding tension. I did 15 complete turns(marked the edge of the socket so I could count good-hehe). Anyway, ride is a little stiffer than the original 318 bars + I added a factory swaybar.

Somewhere, in the tech archives.....I'm sure Carl has installed something in the suspension section. You basically wind up the T bars, bounce the car around a little and go underneath and measure from the lower control arm to a level floor, in 2 places. There is a factory spec for this, though I can't remember what it is at the moment. Once close....take a ride, come back and double check/final tweak. You can add a little height or take it away....but once you are set on height, go get the front end properly aligned afterwards. Anytime you make an adjustment....take it for a drive, or bounce the heck outta it and remeasure.

========================================

Michael

Moparts Member

Posts: 3325

From: Bridgeport,WV USA

Registered: Nov 1999

posted 11-15-2002 10:08 PM

I went one step bigger than the Hemi bars---luv them.

===========================================

dbdartman

Moparts

Posts: 3934

From: Trenton, NJ

Registered: Nov 1999

posted 11-15-2002 10:16 PM

HEMIRR68, you might want to check the location of the original poster. DRIVER'S SIDE IS THE RIGHT SIDE IN OZ!!! Hope you didn't confuse the poor boy.

Aussie, check in the tech archives, there should be a few different methods of removing T-bars posted there, some of which require no special tools.

DB

Torsion bars??? Roadrunner advise

snipe4stuff

New Member

Posts: 63

From: marshall TX USA

Registered: Aug 2002

posted 01-18-2003 10:37 PM

Hi someone told me iam new to mopars that you could raise the front by turning in the torsion bars ? is this so the front end is really low on my car makes nice flat header tubes how is this done safely Thanks

==========================================

d100

Moparts Member

Posts: 1272

From: pittsburg, ks.

Registered: Apr 2002

posted 01-18-2003 10:43 PM

clockwise raises it and counterclockwise lowers it.

=========================================

waveraider!

Moparts Member

Posts: 1028

From: Indianapolis

Registered: May 2001

posted 01-18-2003 10:55 PM

Keep in mind if you crank up the torsion bars you will also need to get your front end aligned. It still beats flat headers.

===========================================

70 440-6 RR

Moparts Member

Posts: 1549

From: Upstate New York

Registered: Dec 1999

posted 01-18-2003 11:00 PM

Park in a level spot and measure from the front fender lip to the ground on both sides. Check the rear too. I would tighten both sides about two full turns on the wrench and see what kind of change it made. Repeat as necessary! The ruler will tell you if you are doing it unevenly.

=========================================

d100

Moparts Member

Posts: 1272

From: pittsburg, ks.

Registered: Apr 2002

posted 01-18-2003 11:17 PM

one turn equals nothing, every car is different for some reason. one car may take 1 turn to get an inch and another may take three turns to get an inch. its all trial and error and i can gaurantee you will have to turn each side a different amount to get it level.

==========================================

beeper71

New Member

Posts: 78

From: wisconsin

Registered: Jan 2003

posted 01-18-2003 11:25 PM

Once you get it at the height you want make sure you have an alignment done or say good buy to your tires.

=======================================

Quick Kurt

Moparts Member

Posts: 3416

From: Pittsburgh, Pa, USA

Registered: Jan 2002

posted 01-18-2003 11:37 PM

The torsion bar adjusting bolt is in the middle of the lower control arm. tighen to raise the front end, and loosen to lower.

Try to turn both sides the same amount.

===========================================

jpav

Moparts Member

Posts: 1071

From: Santa Cruz, CA

Registered: Jul 2000

posted 01-18-2003 11:45 PM

Throw a floor jack under the front end, so the wheels hang free. Makes it a lot easier to turn it up higher, since you are not turning the weight of the car on a single bolt then.

And I'll repeat it again, as everyone else has. If you change the height, get an alignment.

Measure before you jack it up, then make changes. Drive it around the block to allow it to settle, then measure again. Get both sides even before you get the alignment.

Josh

=========================================

Front end rebuild

gts don

New Member

Posts: 82

From: hampton va usa

Registered: Aug 2001

posted 01-18-2003 04:56 PM

Today I disasembled the front suspension on my 69 Dodge Dart. After loosening the adjustment bolt(for the ride heigth)and removing the front bolt the torsion bars just slid out the rear by hand. Is there something that is missing that keeps the torsion bars from working there way out ? Most people have to beat out their torsion bars.Am I just lucky or is there something missing ? I dont want these things to work out at the dragg strip.Also what is a good new torsion bar to install in a small block Dart.Is there any way to get the camber back after lowering the car about 2 inches ?

=====================================

coronet

Moparts Member

Posts: 187

From: Ohio

Registered: Dec 2001

posted 01-18-2003 05:02 PM

You are lucky they just slipped out that easy. There should be a wire clip holding the bars in. I just finished putting my front end together today on this purple P.O.S.

=====================================

carl

Moparts

Posts: 9504

From: Ohio

Registered: Nov 1999

posted 01-18-2003 05:02 PM

There 'should' have been a little wire spring clip in the rear TB socket on the trans crossover. thats keeps the bars in the socket. and the tension on the bars will keep them from backing out in most cases.

The camber can be adjusted back by using the offset upper control arm bushings from moog.

===================================

kekoakeakane

Moparts Member

Posts: 1142

From: Honolulu, HI USA

Registered: Jun 2001

posted 01-19-2003 04:57 AM

As carl said, there should've been a clip at the rear of the bar to retain it in the socket of the frame. I'll bet that your lower control arm bushing is shot and that's why you didn't have to beat the bar out. A properly installed lower control arm and bushing will have the torsion bars always slightly preloaded no matter how far you undo the adjuster. That's because you don't torque the LCA stub shaft nut until the weight of the car is on the suspension and ride height adjusted. This puts the bushing in a neutral state at ride height. It also puts the bushing in a preloaded state when the suspension is unloaded. That's why the trick of undoing the LCA nut and prying the arm back works because it unloads the bushing.

If your bushing is shot, there is no preload, and your T-Bar slides right out.

Kekoakeakane

================================

Tech Index